3

Save these instructions.

For your safety, read, understand, and follow the information provided with and on this jack.

The owner and operator of this equipment shall have an understanding of this jack and safe operating procedures before

attempting to use. The owner and operator shall be aware that use and repair of this product may require special skills

and knowledge. Instructions and safety information shall be conveyed in the operator's native language before use of

this jack is authorized. If any doubt exists as to the safe and proper use of this jack, remove from service immediately.

Inspect before each use.

Do not use if broken, bent, cracked or damaged parts are noted. Any jack that appears

damaged in any way, or operates abnormally shall be removed from service immediately. If the jack has been or

suspected to have been subjected to a shock load (a load dropped suddenly, unexpectedly upon it), immediately

discontinue use until jack has been checked by an KTI authorized service center. It is recommended that an annual

inspection be done by qualified personnel. Labels and Owner's Manuals are available from manufacturer (see Replacement

Parts section).

PRODUCT DESCRIPTION

KTI Transmission Jacks are designed to be used as an aid in the removal and installation of vehicle component parts

and assemblies, specifically transmissions. Model Nos. KTI-63503, KTI-63504 and KTI-63505 are for use under an

overhead lift or in a garage pit. The air actuated function is an added feature of Model No. KTI-63504. Model No. KTI-

63511 is for use under portable lift equipment, where vehicle must be supported by appropriately rated jack stands. With

Model KTI-63504, ensure that your air source can dedicate 7.8 CFM @ 90 - 175 PSI to each jack operated. To ensure

dependable, trouble free operation an air dryer and oiler is recommended.

Product appearance may differ slightly from this publication due to improvements in manufacturing, design

and materials. However, performance characteristics will not be adversely affected.

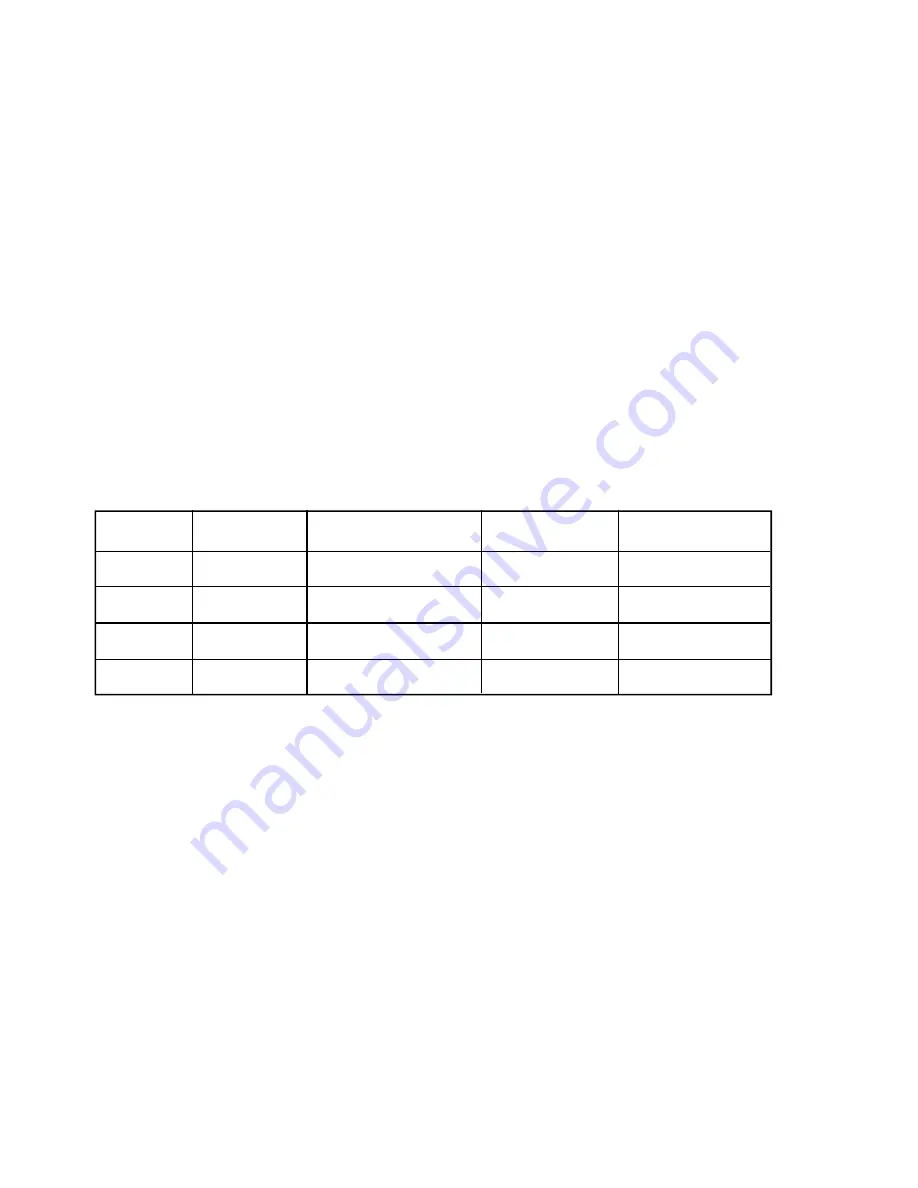

SPECIFICATIONS

Model

Capacity

Base Size ( L x W )

Min. Height

Max. Height

1000 Lbs

33-1/8" x 35-1/2"

37-7/8"

77-5/8"

1000 Lbs

34-1/8" x 36-1/8"

37-7/8"

77-5/8"

2000 Lbs

39-3/8" x 19-1/8"

7-7/8"

33-1/2"

KTI-63503

KTI-63504

KTI-63511

48-5/8"

KTI-63505

2000 Lbs

42-1/8" x 39-1/2"

77-3/8"