W W W . K A A R T A . C O M

8 2

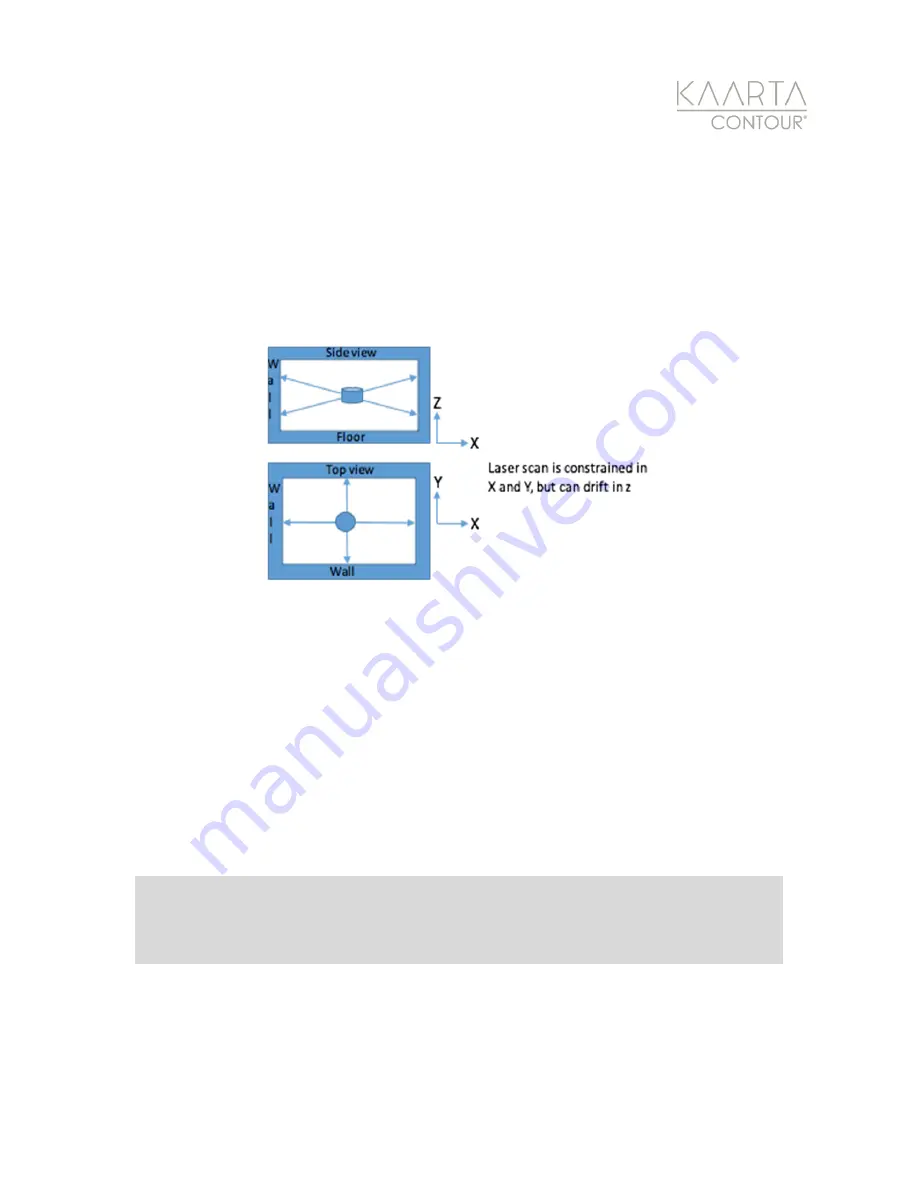

S M A L L R O O M S / N A R R O W H A L L W A Y S

The modeling technology in Contour relies on scan matching to achieve its high level of

accuracy, but every modeling system has limitations. These methods have difficulties

handling extruded environments. Smaller rooms, tunnels, sewers, and hallways are

constrained in two axes (walls, ceiling, and floors), but are unconstrained along the third

axis (Figure 57).

Figure 57: Diagram of hallway drift.

R E F L E C T I O N S

There are some types of surfaces that are more challenging to scan than others, including

shiny, metallic, or reflective features. These surfaces cause the light to be distorted in such

a way that it interferes with the data acquisition process. For shiny and reflective surfaces,

the light scatters and bounces in uncontrollable directions, resulting in false features.

Figure 58 shows an example of bad data due to reflectivity. The wall at the bottom of the

pointcloud is reflected into the scanner through the mirror and registered incorrectly at the

top of the pointcloud (see Figure 58). The scanner cannot distinguish between in-line and

reflected data. This can be cleaned up by manually removing the reflected points.

Scan Tip:

Consider covering mirrors or other highly reflective surfaces prior to

scanning. An easily removeable covering, such as masking tape or temporary

developer spray, can be applied to highly reflective surfaces.