7

Operational Check

Perform the operational check prior to installing the Lock assembly. If the G-152 has been previously

installed, perform the operational check prior to closing

the door.

Make an operational check of the unit by performing the

following actions. (See Figure 15 for reference.)

1. Connect the Lock Body and input unit cable.

2. Activate the input unit by pressing and releasing the

RED switch button.

3. "Open" will appear on the LED display.

4. Insert (latch) the operating handle locking pin into the

lock body.

5. Press and release RED switch button.

6. Press and release RED button again with "UNLK"

prompt.

7. GREEN light flashes.

8. Present Test Card to input unit transponder "RFID"

communication area.

9. Turn dial on lock body to the left to release the handle.

10. Lift operating handle.

Operational check complete.

Battery Maintenance - Temporary Power

Replace Batteries

The four AA batteries located within the Input Unit should be replaced when the “Battery Low Indicator“

illuminates. To replace batteries, complete the following steps:

1. Remove the input unit from the door (4 mounting bolts) and disconnect cable.

2. Remove the back plate of the input unit (4 screws) and the four AA batteries in the battery retainer.

Replace the batteries with four new high quality AA lithium batteries. Once the batteries are properly

installed, the low battery indicator light will flash.

3. Reattach the back plate of the input unit.

4. Reconnect the cable and reinstall input unit.

5. Before closing the door, perform an operational check of the lock with the appropriate opening

procedure as defined for the input unit.

Temporary Power

An external 9V supplementary power connector is provided to supply temporary power to the input

unit. The 9V connector is located at the base of the input unit and is accessible by turning the

knurled knob. It is recommended that you use a new high quality battery.

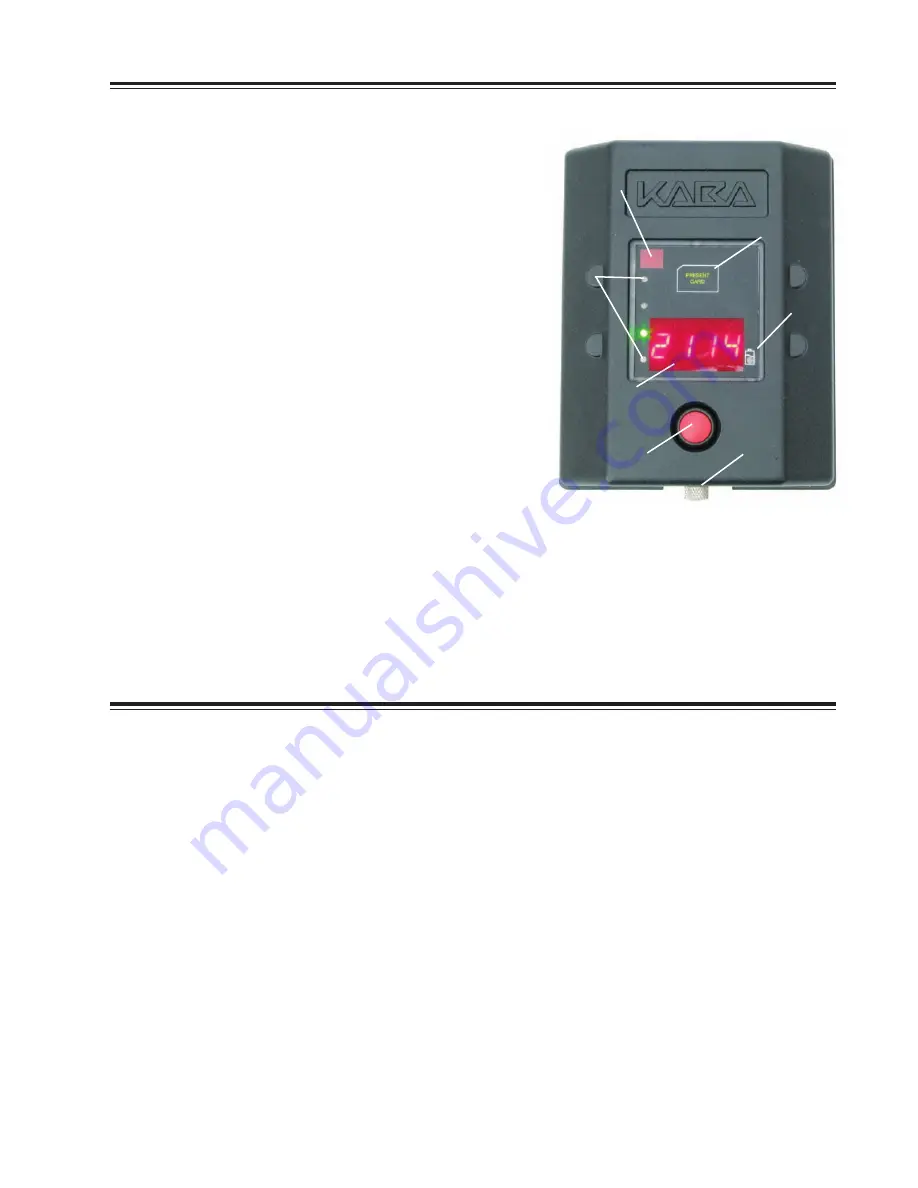

Fig. 15 - Input Unit Operation

Access to

9 volt connector

Low battery

indicator

Transponder RFID

communication area

IrDA

®

port;

Communication with

Pocket PC/Smart Phone

LED Lights;

Operational

prompts and

lock status

Switch activates

unit and enters

user cdes

LED displays

seal number

and operational

prompts