Operating Manual

Installation

19

k1evo821 - 201606

Kaba mechatronic cylinder surface

Round profile

4.2

Installation with body cut-out

4.2.1

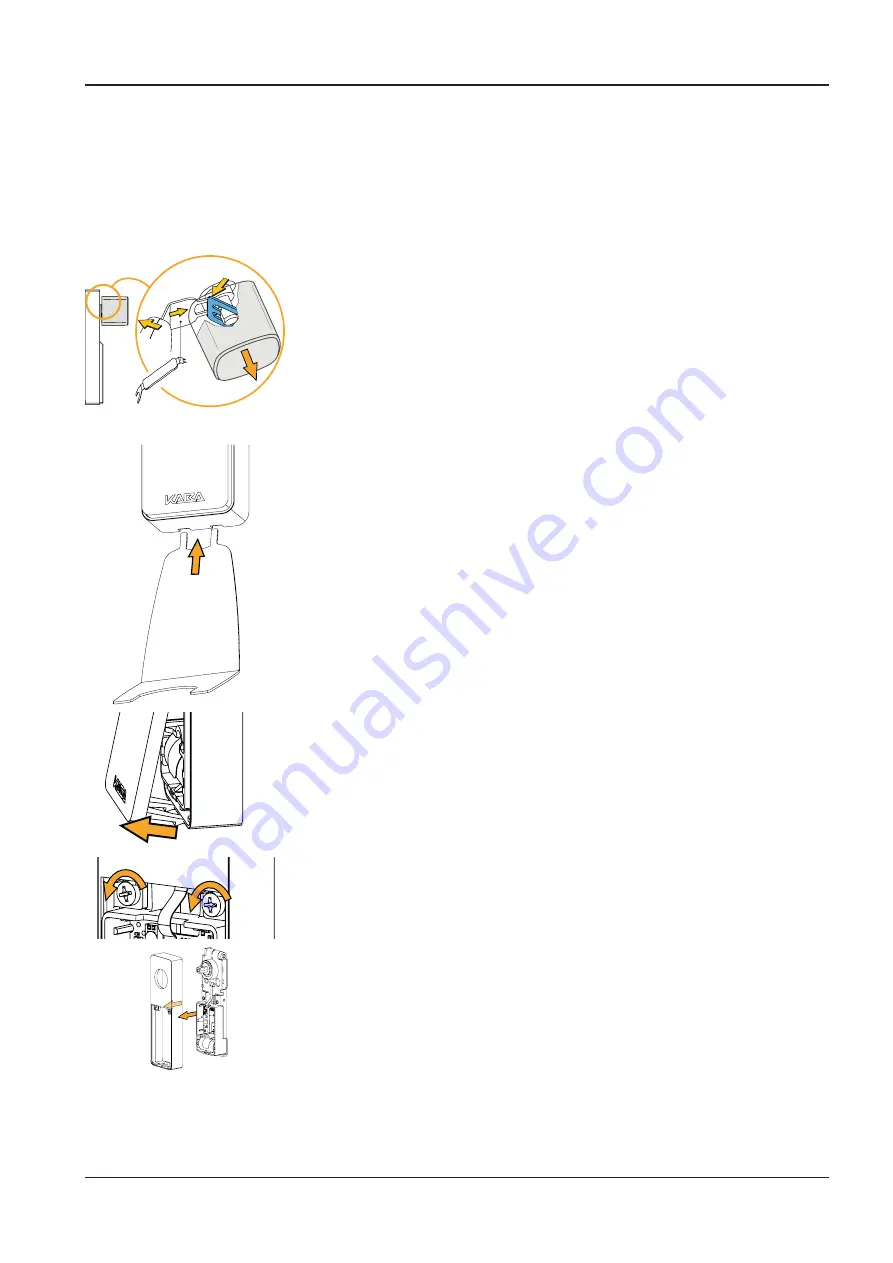

Dismantling the rotary knob

The rotary knob must be dismantled for installation with a rotary-knob cylinder.

ü

Tool – multitool available

1. Insert the multitool with the narrow pawl between the Knob and the fitting.

2. Press the multitool against the fitting.

ð

The locking spring will release.

3. Remove the Thumbturn knob.

4.2.2

Dismantling the housing

1. Push both catches upwards using the multitool.

ð

The catches will be released.

2. Remove the cover by pulling the bottom section forwards.

3. Remove the battery.

4. Undo both screws.

Note:

Only undo the screws as far as necessary for the housing to be removed.

ð

Both screws remain in the housing.

5. Remove the housing.