Section 2 - 14

P

ro

d

u

c

t

In

fo

rm

a

ti

o

n

OMNILOCK

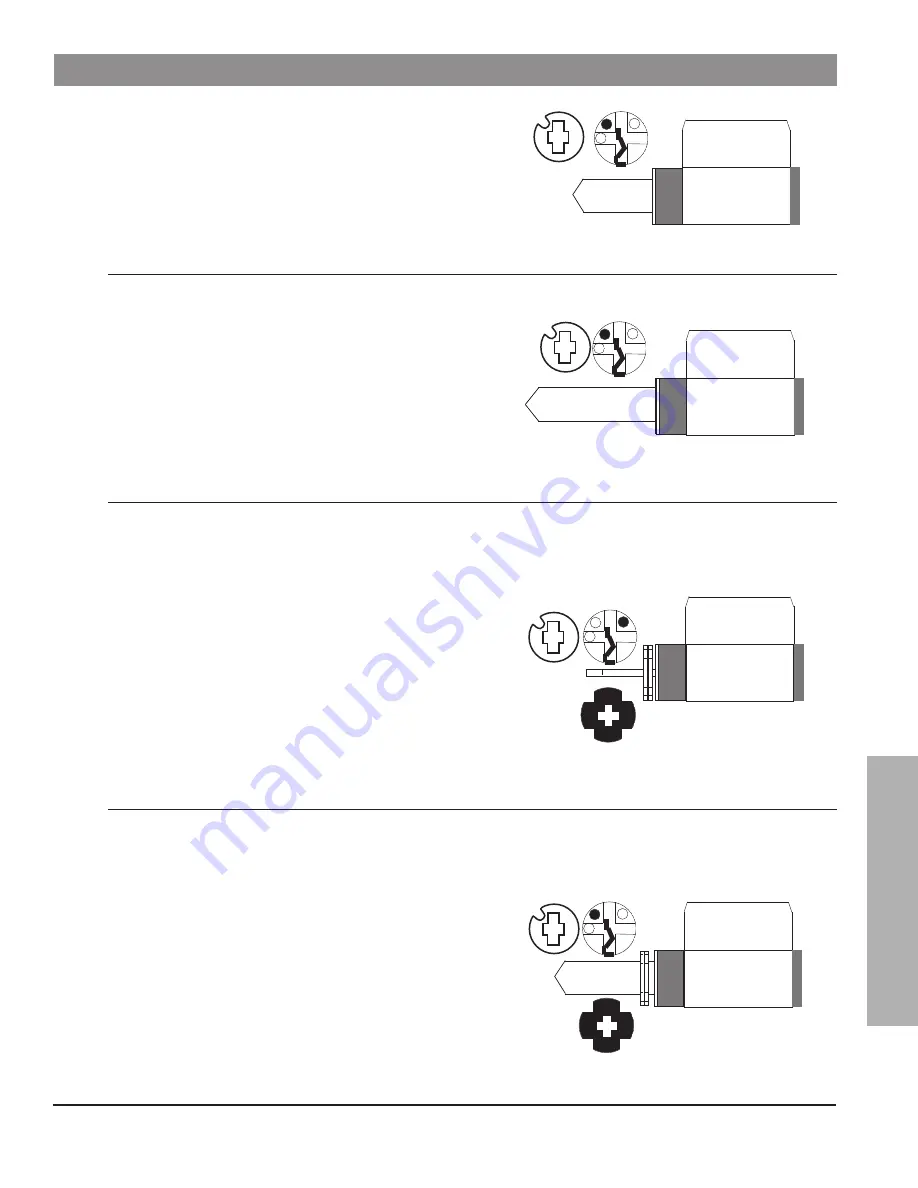

Lever, key by-pass

5400-xx-1099 uncombinated and use:

1590-80-2000 SD/3A tailpiece, vertical

3450-80-2003 spacing washer

SD/3A

"99" plug & shell

large diameter

plug requires

J or K series

bottom pins

PDQ

SK, SP & ST levers (U.S.A.)

5400-xx-1099 uncombinated and use:

4700-80-2002 S/3C tailpiece, vertical

3450-80-2003 spacing washer

S/3C

"99" plug & shell

large diameter

plug requires

J or K series

bottom pins

PDQ

Imported SV grade 2 knobs using Ilco 7056

or Lori 1539 cylinders and 3A or SV tailpieces

5400-xx-1099 uncombinated and use:

1590-80-2000 SD/3A tailpiece, horizontal

3450-80-2003 spacing washer

two 4700-00-4007 metal washers, tailpiece

PDQ

Imported grade 1 Levers (prior to U.S.A. Spirit Levers)

5400-xx-1099 uncombinated and use:

4700-80-2001 SA/3B tailpiece, vertical

3450-80-2003 spacing washer

two 4700-00-4007 metal washers, tailpiece

"99" plug & shell

large diameter

plug requires

J or K series

bottom pins

SA/3B

"99" plug & shell

large diameter

plug requires

J or K series

bottom pins

SD/3A

Key-In-Knob Cylinders - 5400 Series

Summary of Contents for 5140 Series

Page 1: ...Technical Manual ...

Page 5: ...Technical Manual Section 1 Introduction ...

Page 11: ...Technical Manual Section 2 Product Information ...

Page 38: ...Section 2 27 Product Information Peaks Global Notes ...

Page 39: ...Technical Manual Section 3 Key Cutting and Pinning ...

Page 62: ...Section 3 23 Key Cutting Pinning Peaks Global Notes ...

Page 63: ...Technical Manual Section 4 Key Control Record Keeping ...

Page 73: ...Technical Manual Section 5 Cylinder Installation Guide ...

Page 84: ...Section 5 11 Cylinder Installation Guide Peaks Global Notes ...

Page 85: ...Section 5 12 Cylinder Installation Guide Peaks Global Notes ...