11

F-7

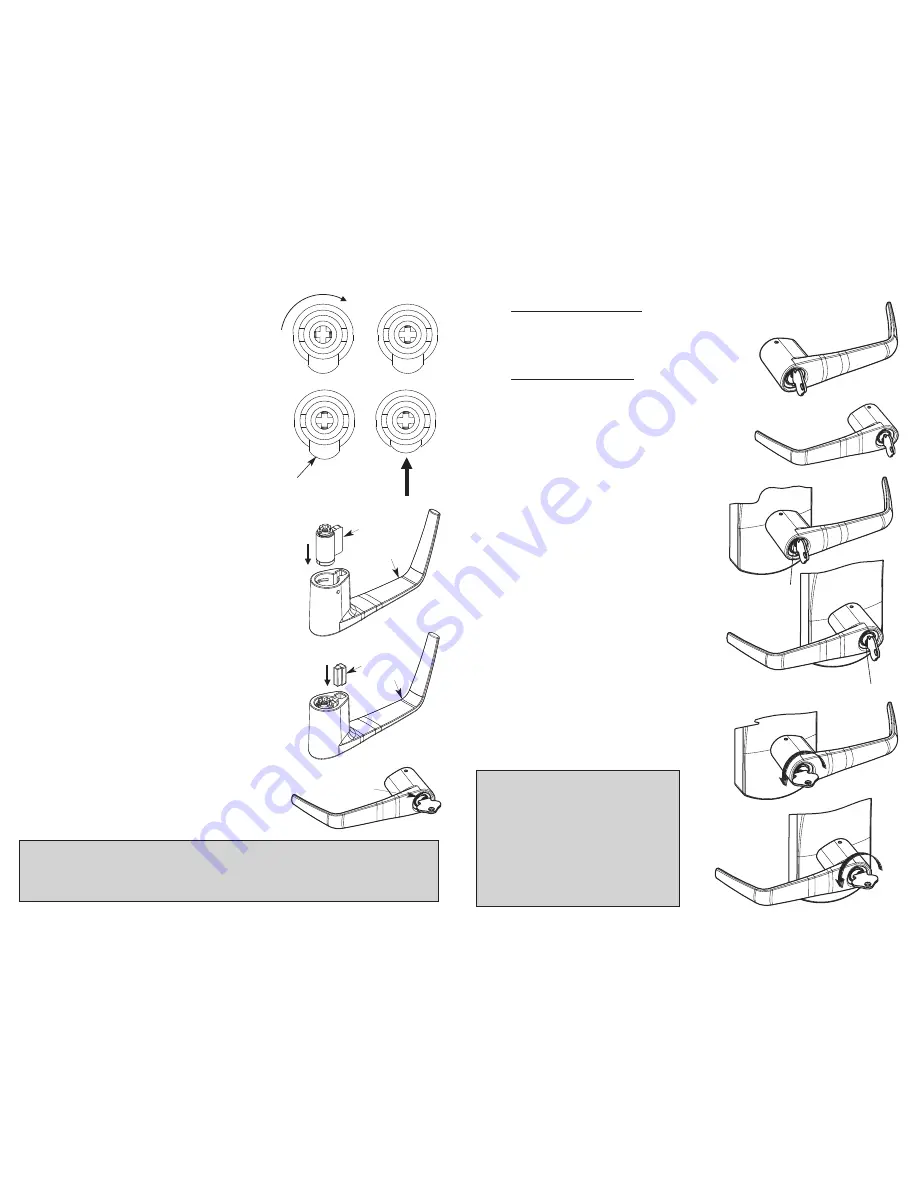

For Right-Handed Levers: Turn the key

approximately 90

º

clockwise so that it is in the

vertical position and the countersink (g) is in

the top position.

For Left-Handed Levers: Turn the key approx-

imately 90

º

clockwise so that it is in the verti-

cal position and the countersink (g) is in the

bottom position.

F-8

Fit the lever handle (h) onto the drive

tube. It should rest approximately

1

⁄

16

"

(2 mm) from the body of the housing.

If it can’t be pushed that close to the

housing, the lever catch (f) is probably

not pushed in. Push it in.

If the lever catch (f) is stuck, the over-

ride shaft is in the wrong position. The

two small indents on the cross of the

override shaft must be vertically

aligned.

F-9

Press the lever firmly against the

housing while turning the key counter-

clockwise (this applies to both Right-

Handed and Left-Handed locks) until it

is in the horizontal position.

Important: If it is not possible to turn

the key counter-clockwise to complete

this step, the spring washer (d) may

be too tense:

Tap the lever carefully with a rubber

mallet to loosen the spring washer (d).

Cover the lever handle with a cloth or

other material to protect the finish of

the metal.

Right-Handed

lock

Countersink (g)

in TOP Position

Countersink (g) in BOTTOM Position

Left-Handed

lock

Right-Handed

lock

Left-Handed

lock

F-2

Turn the override shaft 90

º

clockwise so

that the two small indents on the cross

are now vertically in line. (The cylinder

can be used to turn override shaft.)

F-3

Push in the lever catch firmly.

F-4

Insert the cylinder (j) into the lever handle (h).

F-5

Put the cylinder plug (k) into the lever (h).

F-6

Making sure that the cylinder plug (k) does

not fall out, insert the key into the cylinder

(j). The key will be horizontal.

Caution: The position of the key is very important. If the lever is not assembled

with the key in the correct position before placing the lever on the housing, the

inside mechanism of the lock could be damaged if the lever is rotated and

forced.

10

Countersink (g) in

the top position

Countersink (g) in

the bottom position

h

h

j

j

k

f