PK3520_09_07 • REMOTE ACCESS CONTROLLER - 660G XT

10

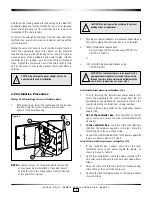

Step 6: Connect wiring

CAUTION: Do not exceed the maximum cable length

indicated by the manufacturer of products being

connected.

!

CAUTION: Refer to the wiring diagram in Annex A, or

refer to label located inside the enclosure's cover.

Follow the applicable steps depending on what

peripherals need to be installed.

!

IMPORTANT: Every wire for the peripherals and power

adaptor must pass through a strain relief as connected

per Step 4.

!

IMPORTANT: For peripherals, choose the appropriate

wire gauge depending on the distance between the

peripheral being installed and the controller board (B)

Refer to manufactures wire gauge installation selections.

Respect all building codes and local legislation relative

to the wiring required.

!

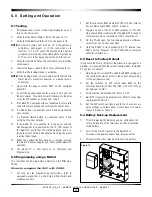

1.

If the controller box is to be interfaced to a fire alarm

panel, remove the jumper wire connected between pins

3 and 4 of J18 on the controller board (C) and complete

the fire panel installation as desired.

2.

If a request to exit (REX) button (S) is being used, mount

the button at the desired location and run a 2-conductor,

cable from the control panel to the REX button location.

Connect as per Annex A, Table 1.

NOTE:

Refer to manufacturer’s wire gauge installation

selections.

NOTE:

A motion detector may also be used for request to exit.

If this is required, use the same connection instructions

as indicated above.

3. If a remote unlock button (U) is being used, mount the

button at the desired location and run a 2-conductor

cable from the controller board (C) to the remote unlock

button location. Connect as per Annex A, Table 1.

NOTE:

Refer to manufacturer’s wire gauge installation

selections.

4. Install a 2-conductor cable from the control panel to the

location of the electric strike (Q) or electromagnetic lock

(R). Connect as per Annex A, Table 1.

NOTE:

Refer to manufacturer’s wire gauge installation

selections.

5. Install the diode across the terminals of the electromagnetic

lock (R) or, using the crimp connectors (AC) provided in

the hardware bag, install the diode across the two wires

of the electric strike (Q). Do not reverse the diode polarity,

as indicated on the wiring diagram in Annex A.

CAUTION: Diode must not be in contact with

electromagnetic lock (R) or electric strike (S), or a

short could be created. Diode ends might need to be

cut shorter.

!

NOTE:

This step is not necessary if installing a Rutherford

Controls 83xx series electromagnetic lock.

6. Following local building code requirements, mount the

electric strike (Q) or electromagnetic lock (R) or Garage

Door Opener (V) in the desired location and connect as

per manufacturers’ instructions. For connections into the

Controller box, connect as per Annex A Table 1.

7. If the Tamper switch needs to be connected to the

premise alarm system, disconnect the wires from J7-1

and J7-2 and run a 2-connector cable from the tamper

switch to the premise alarm system.

IMPORTANT: The tamper switch’s polarity is such that

when the door is closed the switch itself is also in a

closed state. Ensure that the wiring to the premise alarm

system is done accordingly to prevent false alarms.

!

Step 7: Mounting and wiring keypads

NOTE:

All keypads must be installed on a flat surface.

Up to two keypads can be installed with the 660G XT; one

ingress and one egress.

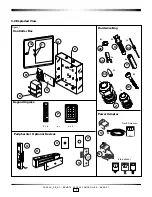

Figure 10

3 x 4 Wall mount

or

2 x 6 Narrow

4.0 System Installation Overview

(Continued)