EN

Page 9

Errors and modifications excepted.

09.02.2009

Mounting Instructions Mechanical Combination Locks

LA GARD 947/ 985/ 3330/ 3332/ 3370/ 3390

the bolt or the relocker might be damaged.

With the lock 1947 the lever has to be dropped and the bolt has to be slid-in before the cover

can be assembled.

Lock 3370:

Removing the cover is not necessary for mounting the 3 screws. Just fit the screws from

behind the lock through the cover and the housing.

Lock 3390:

Removing the cover is not necessary for mounting the 3 screws. Just fit the screws from

behind the lock through the cover and the housing. The short screw fits in the hole with the

circular mark. Note: The bolt must remain in the retracted position during the entire installation

process. If the bolt becomes extended during the installation process, open the lock according

point 8. and continue the installation. After mounting and testing lock and dial, install the cover

insert. Press the insert into the cover using even pressure. The insert is designed to prevent

spline key movement.

The bolt work must block the extended bolt (8 mm) sufficiently on both sides (in opposite

directions). If only one side is blocked and the bolt pressure exceeds 1 kN, a bolt support must

be fixed on the opposite side. The tolerance between closing point respectively support and

bolt is 0.5 - 1 mm, the bolt counter pressure is 1 KN max.

If parts of the bolt work are attached to the bolt (option code RLG004 or RLG005), see point

10.

4. Dial assembly

The LA GARD dial & ring combinations 1730/ 1731/ 1777/ 1779/ 2085/ 2107 have a spindle

with US-thread 5/16-40 UNS-2A and the dial is splined on 43.

Assemble the ring so that the Opening Index is vertical. Cut the spindle so that the spindle-end

levels with the cam. The spindle must not stick out. Carefully thread (clockwise) the spindle

into the drive cam until tight. Next, rotate (counter-clockwise) approx. 1 turn until the groove in

the spindle is aligned with the correct spline position. Tolerance approx. 0.5 mm axial.

VdS Class 3/CEN C: 1947 is only approved with the dial 1730/1731. The spindle lead through

of the safe door must have a diameter of 10-12 mm.

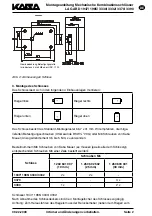

5. Spline key position

Depending on the installation of the lock, 4 spline key positions are possible. They are indi-

cated on the cam: RH, LH, VU, VD.

The correct spline key position is very important, because otherwise the „prohibited area“

(last number not between 0-20) moves in another operational range and might lead to lock

malfunctions.