Section 3 - 16

K

e

y

C

u

tt

in

g

&

P

in

n

in

g

Calculating Small Format Interchangeable Core – A2 System Pin Stacks

A2 system has ten depths numbered 0 to 9, shallow to deep, respectively. Two step progression must be used

to prevent key interchange. In A2 system, parity must be maintained in each position, i.e., only the odd or even

cuts may be used in a given pin chamber.

When a key system is written, the choice of a TMK automatically determines the parity pattern. Section 4 of this

Manual has forms with all sixty-four parity patterns to use in maintaining a TMK register. This can also be done

with a computer and data base program.

The operating and control shear lines are distinct in all positions. All the operating keys work at the plug (oper-

ating) shear line. Only the control key works at the control shear line.

Pin to the operating keys first. The shallow cut determines the bottom pin. A master pin makes up the difference

between shallow and deep operating cuts. The numerical value of the bottom pin and master pin together is

called the “plug total”. For example, a #3 bottom pin plus a #4 master pin results in a plug total of 7.

Buildup pins are added to the plug total to make the control key operate at the control shear line. Top pins are

added to achieve a uniform pin stack height of 23 in all chambers.

Non-original pins will not work properly in Kaba products and their use voids product warranty.

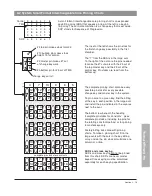

Calculating the pin stack

3. Add a top pin to bring the total pin stack to 23.

2. Add 10 to control bitting. Subtract plug total.

The remainder is the buildup pin.

1. Pin operating keys to the plug shear line.

The plug total equals the deep operating bitting.

add top pin to

make stack total 23

buildup pin equals

control cut + 10

minus plug total

master pin equals

the larger of the

master key or oper-

ating key cut minus

the bottom pin

bottom pin equals

the smaller of the

master key or oper-

ating key cuts

plug total

Summary of Contents for Peaks Preferred

Page 1: ...Technical Manual Preferred Classic ...

Page 3: ...Peaks Preferred Classic Notes ...

Page 4: ...Technical Manual Section 1 Introduction Preferred Classic ...

Page 12: ...Technical Manual Section 2 Product Information Preferred Classic ...

Page 19: ...Section 2 7 Product Information Peaks Preferred Classic Notes ...

Page 41: ...Section 2 30 Product Information Peaks Preferred Classic Notes ...

Page 42: ...Section 2 31 Product Information Peaks Preferred Classic Notes ...

Page 43: ...Section 2 32 Product Information Peaks Preferred Classic Notes ...

Page 44: ...Technical Manual Section 3 Key Cutting and Pinning Preferred Classic ...

Page 66: ...Section 3 22 Key Cutting Pinning Peaks Preferred Classic Notes ...

Page 67: ...Section 3 23 Key Cutting Pinning Peaks Preferred Classic Notes ...

Page 68: ...Preferred Classic Technical Manual Section 4 Key Control Record Keeping ...

Page 79: ...Section 4 11 Key Control Record Keeping Peaks Preferred Classic Notes ...

Page 80: ...Preferred Classic Technical Manual Section 5 Cylinder Installation Guide ...

Page 91: ...Section 5 11 Cylinder Installation Guide Peaks Preferred Classic Notes ...