15

O-3

Resetting and Recovery of Current Code

To reset the code gears (a), each one of the 5 “L” shaped

legs (b) of the unlocking slide (c) must engage snugly

with the corresponding code gear pocket (d) next to it.

Position the chamber in one hand, as

shown. Hold chamber by the top screw tab

(e) and bottom screw tab (f).

Rotate the reset cam (g) back toward you

with your finger, towards the key stems (h) as far as it will

go and then release. Now look at the code gears (a) and

the unlocking slide (c). Note that some or all 5 of the code

gear pockets (d) are rotated away from the “L” shaped

legs (b) as if out of alignment. Typically each code gear

pocket will be at a slightly different distance compared to

the other.

Note:

Sometimes

two different

gear pockets are away from alignment

by

exactly the same distance

– this indicates that the current code uses

two

different number buttons

(example, 2 and 4)

depressed at the same time

as part of the code combination.

Using a small flat blade screw driver or your thumbnail, depress the key

stem which corresponds to the gear pocket which has been rotated the

farthest away

(out of alignment) from the “L” shaped leg. When

depressed, the key stem(s) should stay down and the corresponding

gear pocket(s) should move closer to its corresponding “L” leg, closer to

alignment. Record the key stem number. This is the

first

number of your

combination.

Note:

If two gear pockets are at the

same distance

, depress

both

of these corresponding key stems

at the same time

.

Continue by pressing the key stem that corresponds to the gear pocket

that was the

next furthest away

(do not include gear pockets that have

already been rotated). Record each key stem number that is depressed.

Continue this procedure until all five gear pockets are aligned with their

corresponding “L” shaped legs on the unlocking slide. The combination

is the recorded numbers, in the order recorded.

Note:

If you depress the wrong key stem by mistake, rotate the reset cam

back toward you, (toward the key stems and release). This resets the code

gears and you must repeat the above procedure, O-3.

14

N.

INSTALLING RUBBER BUMPERS

N-1

Close the door and apply pressure making sure

the deadlatch (a) rests on the strike plate (b) as

shown. Standing on the frame (door stop) side of

the door, check for gaps between the door and

the frame on the three sides of the frame (left,

right, and top).

N-2

Mark locations where the gaps are approximately

3

⁄

16

" (5 mm). Make sure these locations are free

from grease and dust. Peel the bumpers (c)

(supplied) from their protective backing without

touching the adhesive surface and stick them on

the marked locations.

Note:

Allow 24 hours for adhesive to set before testing.

The door may be operated normally during this time.

O.

HOW TO RESET A LOST OR

UNKNOWN COMBINATION

There is no way to determine a forgotten, unknown or lost combination code

from the front or outside of the lock. However, it can be reset and recovered

or reset and changed to a new code by following the steps in this section.

Warning:

Since this procedure is of a technical nature, only technically trained

personnel in the lock and hardware field should undertake this operation. For

further assistance, call the Kaba Access Control technical support line at

800-849-TECH (8324) or 336-725-1331 between 8AM and 5PM Eastern

Standard Time, Monday through Friday (except holidays).

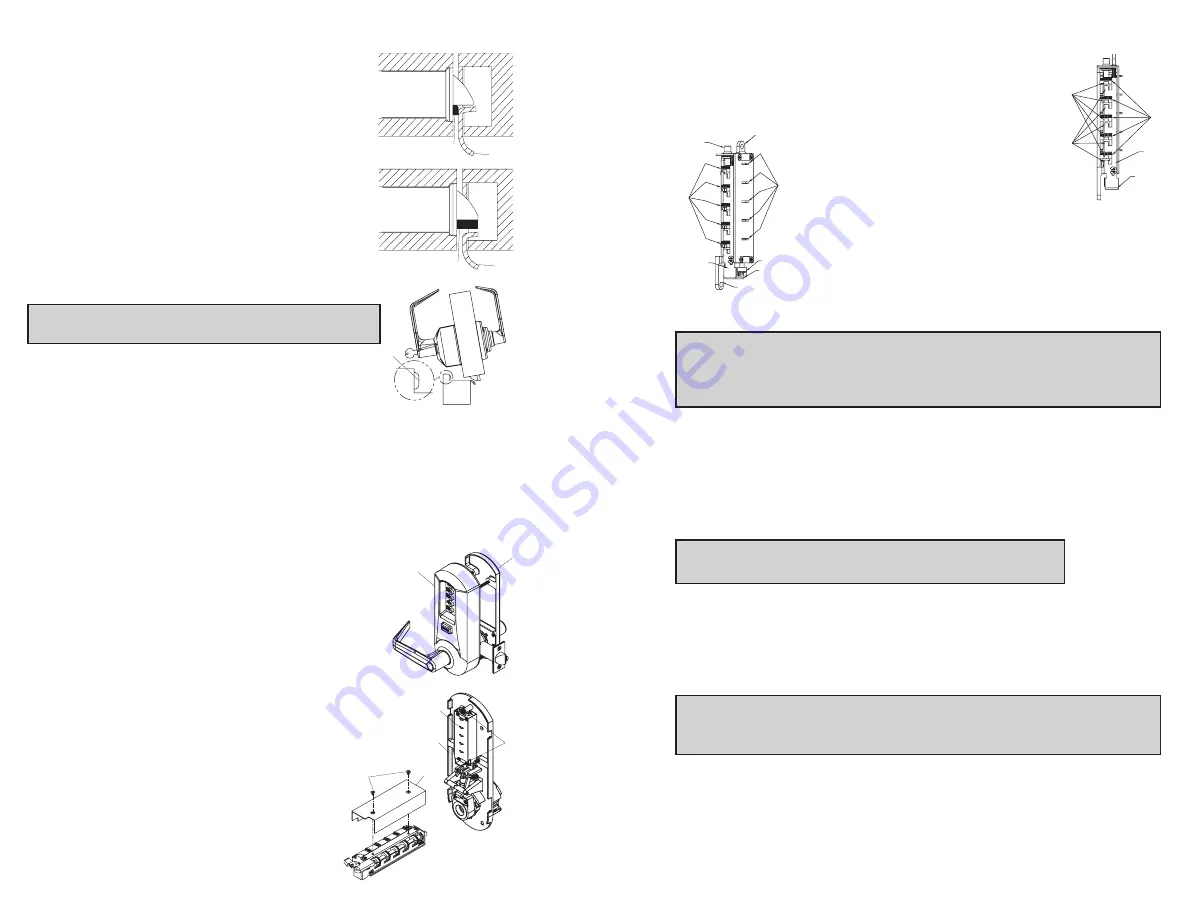

O-1

Removing Lock From Door

Remove both the outside unit assembly (a) and the

inside unit assembly (b). (Reverse procedures from

sections E and F of this manual.)

O-2

Removing Combination Chamber Assembly

Carefully remove the base plate of outside unit

assembly (a) by removing the 2 Phillips screws (one screw

may be found under an inspection sticker).

Remove the combination chamber assembly (b) from the

base plate by removing the 2 Phillips screws (c).

Remove the 3-sided dust cover (d) to fully

expose the chamber by removing 2 small

Phillips screws (e). (May be 1 screw (x) in

newer models)

a

b

c

b

a

e

d

(x)

a

c

j

b

d

i

a

c

f

j

g

h

e

c

a

Correct

Incorrect

a

b

b

Summary of Contents for Simplex 5000 Series

Page 12: ...19 18 Notes Notes ...