A.

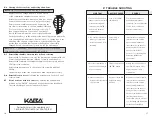

DOOR PREPARATION

A-1

Place paper template (supplied) onto door

and mark for holes. Drill the four

1

⁄

4

" (7

mm) holes first. Next drill the 2

1

⁄

8

" (54

mm) cross bore hole. Drill the 1" (25 mm)

hole last.

A-2

For Models 5041 & 5051 only. When

installing Model 5021, skip to step A-4

.

Passage feature models require an

additional 1” (25 mm) hole in the door face

(see “a” in the illustration to the right).

A-3

For Models 5031 & 5051 only. When

installing Models 5021 or 5041

models,

skip to step A-4

. Inside code change models

require an additional 1” (25 mm) hole in the

door face (see “b” in the illustration above).

A-4

Mortise door edge for latch unit faceplate (c)

1

⁄

8

" (3 mm) deep to dimensions shown. Insert

latch unit into the 1" (25 mm) hole, making

certain that the latch bolt bevel faces

direction of closing door.

Note

: If using a

3

⁄

4

" (19 mm) latch, the edge of the

latch bore hole must be prepped to accomodate

the anti-friction hinge. (The location of the anti-

friction hinge depends on the door handing).

A-5

Secure the latch to the door using two

3

⁄

4

"

(19 mm) combination screws (d) supplied.

Latch unit faceplate must be flush with door (e).

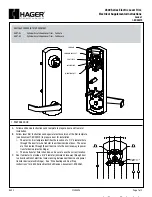

B.

LOCK HANDING

The Simplex 5000 is a non-handed lock that is

preassembled for left-hand door installations.

B-1

Determine the hand of your door. For left

hand doors, proceed to Section C.

For right hand doors, follow steps in B-2.

2

4 x

1

⁄

4

"

b 1" (for models

5031 & 5051)

a 1" (for models

5041 & 5051)

b 1" (for models

5031 & 5051)

Mortise approx.

5

⁄

16

" (8 mm)

extra depth to

allow clearance

of anti-friction

hinge

b 1" (for models

5031 & 5051)

a 1" (for models

5041 & 5051)

a 1" (for models

5041 & 5051)

2

1

⁄

8

"

1"

1

1

⁄

8

"

c

Anti-friction hinge

Anti-friction device

e

d

2

1

⁄

4

"

3

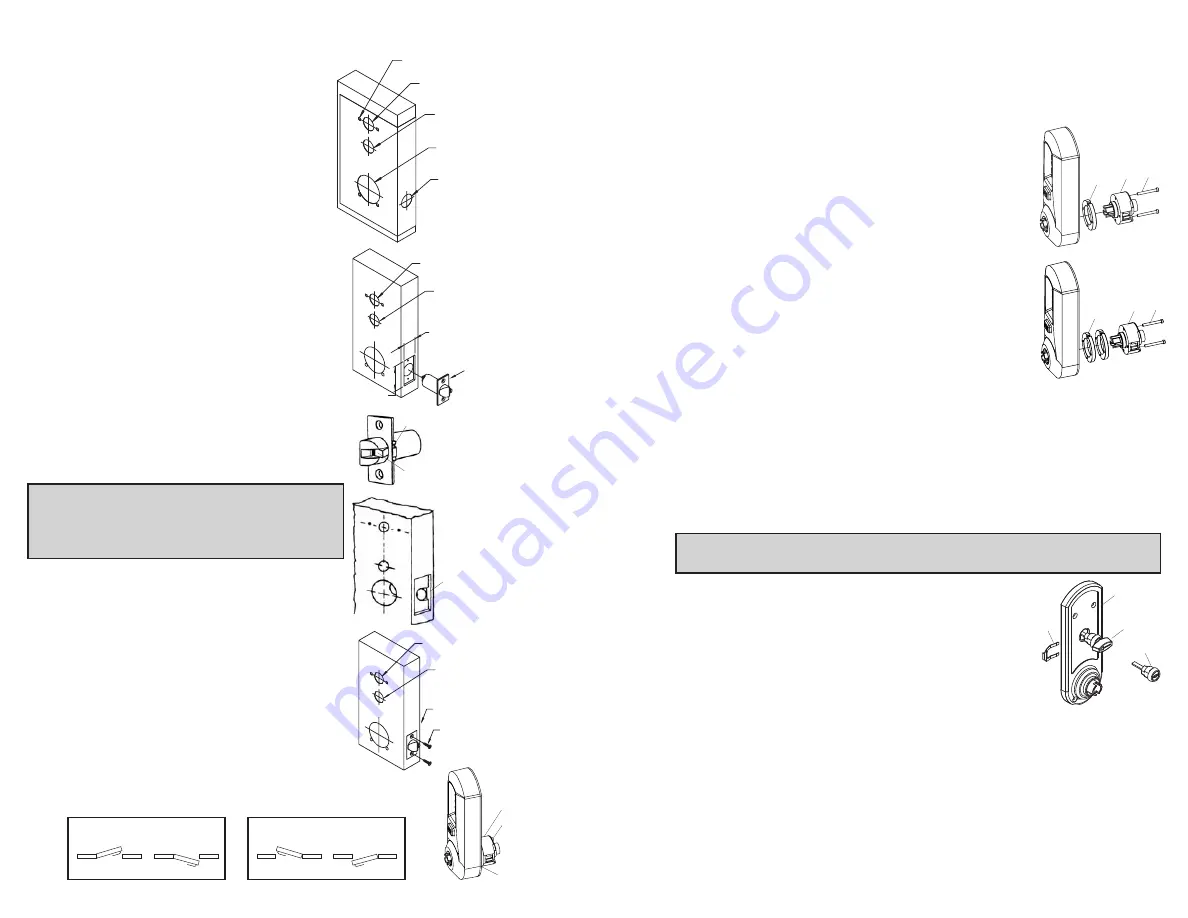

B-2

Remove the two connecting screws (a) from the cylindrical drive unit (b).

Rotate cylindrical drive unit 180 degrees. Reposition spacer (c) as found

before disassembly. Remount drive unit with the two connecting screws.

C.

DOOR THICKNESS

The Simplex 5000 lock is preassembled to

accommodate standard door thickness 1

5

⁄

8

" (41 mm)

to 2" (51 mm).

C-1 (Reference Figure A) For thinner door applications

of 1

3

⁄

8

" (35 mm) to 1

1

⁄

2

" (38 mm)

Remove and

discard the two connecting screws (a) from the

cylindrical drive unit (b). Remove and discard the

spacer (c). Remount the cylindrical drive unit using

the two shorter 1

3

⁄

8

" (35 mm) connecting screws

supplied.

C-2 (Reference Figure B) For thicker door applications

of 2

1

⁄

8

" (54mm) to 2

1

⁄

4

" (57mm)

Remove the two

connecting screws (a) from thecylindrical drive unit (b). Add the extra

spacer(c) supplied. Remount the cylindrical drive unitusing the same two

connecting screws (a) just removed. (Do not over tighten screws)

D.

INSTALLING THE PASSAGE SET

For models 5041 & 5051 only. When installing non-passage models,

skip to section E.

Note:

The end user may choose either a key cylinder (a) or turn knob (b)

actuator to engage the passage function.

D-1

Prior to installing the passage actuator, hold the

chosen actuator housing in one hand, and with the

other hand, rotate the key cylinder or knob

counterclockwise until it stops. If the key cylinder

actuator is used, withdraw the key, which will lock

the cylinder in this position (a detent in the turn

knob locks the cylinder).

D-2

Insert the key cylinder or turn knob assembly (a or b) into the opening

on the inside unit assembly (c). Upon completion, the arrow of the turn

knob should be pointing to the left, or the dot on the face of the key

cylinder actuator should be on the left.

D-3

Secure the passage set assembly with the spring clip (d) from the inside.

Left Hand

Left Hand Reverse Bevel

R

LEFT HAND DOOR

Right Hand

Right Hand Reverse Bevel

RIGHT HAND DOOR

L

c

a

b

b

a

c

b

a

c

c

b

d

a

Summary of Contents for Simplex 5000 Series

Page 12: ...19 18 Notes Notes ...