5

4

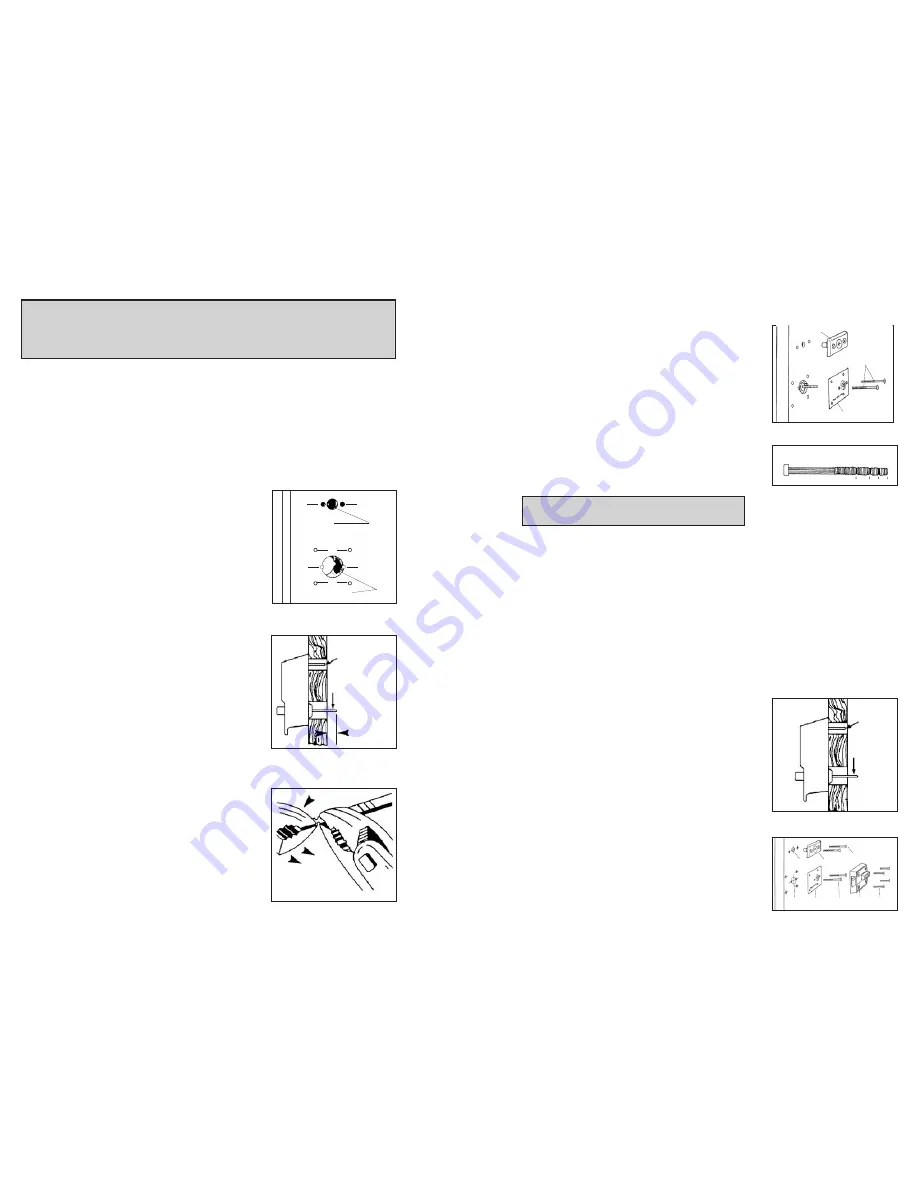

C. DRILLING HOLES IN THE DOOR

CAUTION:

Positioning and drilling must be done straight to ensure trouble

free operation of the model 7106 lockset. Improper drilling may result in

excessive force being exerted on the lock which may result in the premature

wearing of its mechanical parts.

You must do Step 1 first or it will be impossible to drill the four

1

⁄

4

" (6 mm)

holes.

C-1

Use a

1

⁄

4

" (6 mm) drill bit to drill the four holes for the thru-bolts

(See A in

Figure 3-1)

. To prevent splintering the door or breaking the drill bit, begin

drilling at a slow speed and increase the speed gradually until the tip of

the drill bit emerges from the other side of the door. Repeat this proce-

dure from the opposite side of the door.

C-2

Use a hole saw with pilot bit to make the 1

3

⁄

8

" (35 mm) hole (B). Apply

pressure evenly until the circular blade cuts

the first side of the door and the tip of the

pilot bit emerges through the other side, then

stop. Drill from the other side until the 1

3

⁄

8

"

(35 mm) hole is completed.

C-3

Repeat Step C-2 for the

3

⁄

4

" (19 mm) hole

(See C in Figure 3-1)

.

C-4

Drill the four

1

⁄

8

" (3 mm) holes

3

⁄

4

" (19 mm)

deep

(See D in Figure 3-1)

.

D. ADJUSTING THE LOCK

The lock has been pre-assembled to accommodate

doors up to 2

1

⁄

4

" (57 mm) thick. If your door is 1

3

⁄

8

" to 2" (35 mm to 51 mm) thick, you must short-

en both tailpieces

X

and

Y (See Figure 4-1)

and

shorten the (

A

) Two thru-bolts used to secure the

(

B

) combination change assembly.

D-1

Shorten the combination change tailpiece

X

according to your door thickness. Tailpiece

X

has been pre-marked for various door

thicknesses for accuracy and convenience.

a)

After determining the break line, hold the

tailpiece firmly with a pair of pliers on the lock

side of the tailpiece, just beside the desired

break line.

b)

With a second pair of pliers, grip the tail

piece at the other side of the line and bend it

up and down until it breaks

(See Figure 4-2)

.

D-2

While holding the lockset firmly against the outside of the door,

(See

Figure 4-1)

mark tailpiece

Y

at the point where it extends

1

⁄

2

" -

5

⁄

8

" beyond

the interior surface of the door.

a)

After determining the break line, hold the

tailpiece firmly with a pair of pliers on the

lock side of the tailpiece, just beside the

desired break line.

b)

With a second pair of pliers, grip the tail

piece at the other side of the line and bend it

up and down until it breaks

(See Figure 4-2)

.

D-3

Shorten each of the two reinforcing plate thru-

bolts (A)

(See Figure 4-3)

by gripping

at the threaded end with pliers and sawing

through, at the correct length

(See Figure

4-4)

, with a fine-tooth hacksaw.

Note

: Be careful not to damage the threads

when shortening the thru-bolts.

• For 1

3

⁄

8

” (35 mm) thickness doors, shorten thru-bolt at

A

.

• For 1

3

⁄

4

” (45 mm) thickness doors, shorten thru-bolt at

B

.

• For 2” (51 mm) thickness doors, shorten thru-bolt at

C

.

• For 2

1

⁄

4

” (35 mm) thickness doors, leave thru-bolt as is.

D-4

To secure (B) combination change assembly

(See “G” Figure 5-2)

, utilize

two 2" (51 mm) bolts (H) for door thickness 1

3

⁄

8

" (35 mm) to 1

1

⁄

2

" (38 mm).

For door thickness 1

1

⁄

2

" - 2" utilize two 2

3

⁄

8

" (60 mm) bolts (H). For door

thickness 2" - 2

1

⁄

4

", utilize two 3" thru-bolts (H).

E. INSTALLING THE LOCK

The model 7106 lock is packaged for an inward

opening door. For an outward opening door, the

latch must be reversed

(See Section F)

.

Figures 5-1

(outside of door) and

5-2

(inside of

door) show how the lock is installed and identify

each component by letter. Refer to these figures

as you follow the steps below.

E-1

Insert tailpiece (

Y

) into the 1

3

⁄

8

" (35 mm) cutout

(

A

) and the combination change tailpiece (

X

)

into the

3

⁄

4

" (19 mm) hole (

B

)

(See Figure 5-1

and 5-2).

4-1

4-2

1

⁄

2

" -

5

⁄

8

"

(13 mm -

16 mm)

1st

2nd

B

C

4-3

A

5-1

4-4

A

B

C D

3

⁄

4

" (19 mm)

1

3

⁄

8

" (35 mm)

D

A

B

X

Y

X

Y

C

A

A

A

D

3-1

5-2

A

C

D

E

F

B

G

H