2020

080x.000.01.01.01

25

6.2.2

MATBOI 480 T / 650 T

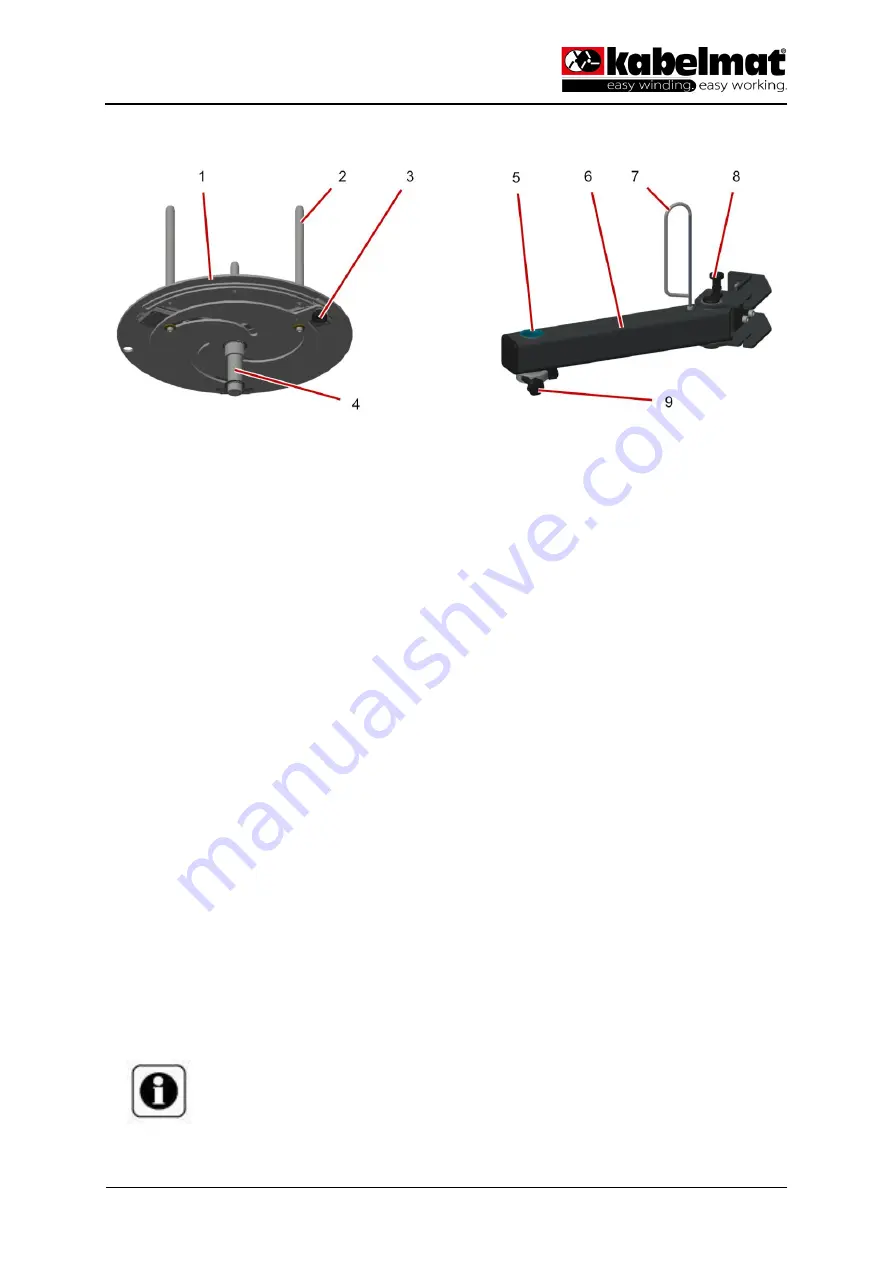

Fig. 17 Adjusting MATBOI 480 T and MATBOI 650 T

1

Bearing plate

2

Clamping bolt

3

Knurled screw for central adjustment of

the clamping bolts

4

Connecting shaft

5

Locating bearing for bearing plate

6

Bearing arm

7

Cable routing

8

Locking bolt swivel arm

9

Star knob brake

Insert ring collar

► Loosen the safety bolt on the swivel arm and swivel the swivel arm outwards until the safety bolt

engages.

► Loosen the knurled screw of the central adjustment of the clamping bolts.

► At the knurled screw, push the clamping bolts inwards via the central adjustment

► Insert ring collar.

► At the knurled screw, push the clamping bolts outwards via the central adjustment.

► Tighten the knurled screw of the central adjustment of the clamping bolts.

► Loosen the safety bolt on the swivel arm and swivel the swivel arm inwards until the safety bolt en-

gages.

► Guide the material through the cable guide and adjust the braking force on the star knob if neces-

sary.

✓

Ring collar is inlaid

Info

If material runs off during unwinding, the braking force must be adjusted.