CONTENTS:

2 #451 Draft Gear Boxes & Lids, 2 #148 WHISKER

®

Couplers, 2

Centering Bushings, 2 0-80 x 1/8” Flat Machine Screws, 2 2-56 x 3/8” Flat Machine

Screws, 2 Bushing Centering Springs, 2 each Assorted Shims, Extra Springs.

This body mounted extended swing gearbox and coupler is designed for

passenger or long freight cars to help negotiate tighter radius curves.

BEFORE ASSEMBLY ALL COUPLERS:

After removing the components from the sprues file off the break away point

and any flash, making sure the inside of the box & V shaped bushing hole is

smooth and burr free. The WHISKER

®

centering spring is a thin wire protruding

at a “V” angle forward from the pivoting hole at the end of the shank. Because

the wire spring is cut by a machine the tips might be sharp and CAUTION must

be taken when handling the coupler. Burnish the coupler shank on both sides.

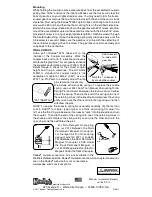

C O U P L E R A S S E M B LY

INSTRUCTIONS

To assemble the coupler

follow the illustrations in these

instructions. See Fig.1 Hold

the lid, coupler & gearbox

assembly together with Kadee

®

#1020 Tweezers according to

the illustration. Then carefully

insert and tighten the 0-80

screw, a magnetic tip screw

driver helps a great deal.

B U S H I N G A S S E M B LY

INSTRUCTIONS

Burnish the bushing & gearbox

w it h # 231 Grea s - e m. To

assemble the rest of coupler

by following the illustrations in

these instructions. See Fig.1

Insert the centering bushing

and invert the assembly. Use our #241 Dual Tool (Manual Uncoupling Tool &

Spring Pic) and insert it between the last two coils on either end of the spring.

Then slip the end of the spring against the bushing and compress the spring

until you can slip the other end onto the spring notch then withdraw the pick

while holding the spring in place. Carefully set the assembly aside but take care

and keep the bushing in place or the spring will come out. The spring is held in

place by the surface the assembly is mounted on.

MOUNTING INSTRUCTIONS

Prepare the surface for mounting. A smooth flat surface is required for mounting

the gearbox to the cars frame.

Option #1

Use the platform end of our #206 Height Gauge to determine how may shims

will be required to build up the underframe to the proper coupler mounting

height. Use the provided shims to build up underframe to 29/64” glue the shims

in place with styrene cement. Find and scribe the centerline on the mounting

surface and shims.

Option #2

If more truck wheel clearance in needed, and where it’s possible, rather the

shimming the mounting surface down to 29/64” use our #42 or #142 Overset

Coupler in the #451 box in place of the #148. The mounting surface is now 1/2”

above the railtop.

451

Extended Swing Gearbox &

Metal Whisker

®

Coupler

Gearbox

C e n t e r i n g

Bushing

2-56 Screw

0-80 Screw

Centering

Spring

Shim

Gearbox Lid

Coupler

Fig.1