Safety and Responsibility

3 --- 12

Operation in Germany:

Recurring inspections in accordance with VBG 16 --- § 18

The company (user) must ensure that recurring inspections of safety devices on com-

pressors with motor power greater than 0.5 kW are carried out by qualified persons.

Inspection intervals of one year are generally sufficient.

Oil change in accordance with VBG16 --- §17

Oil change as required but at least once a year. The oil need not be changed if analysis

shows it to be still useable.

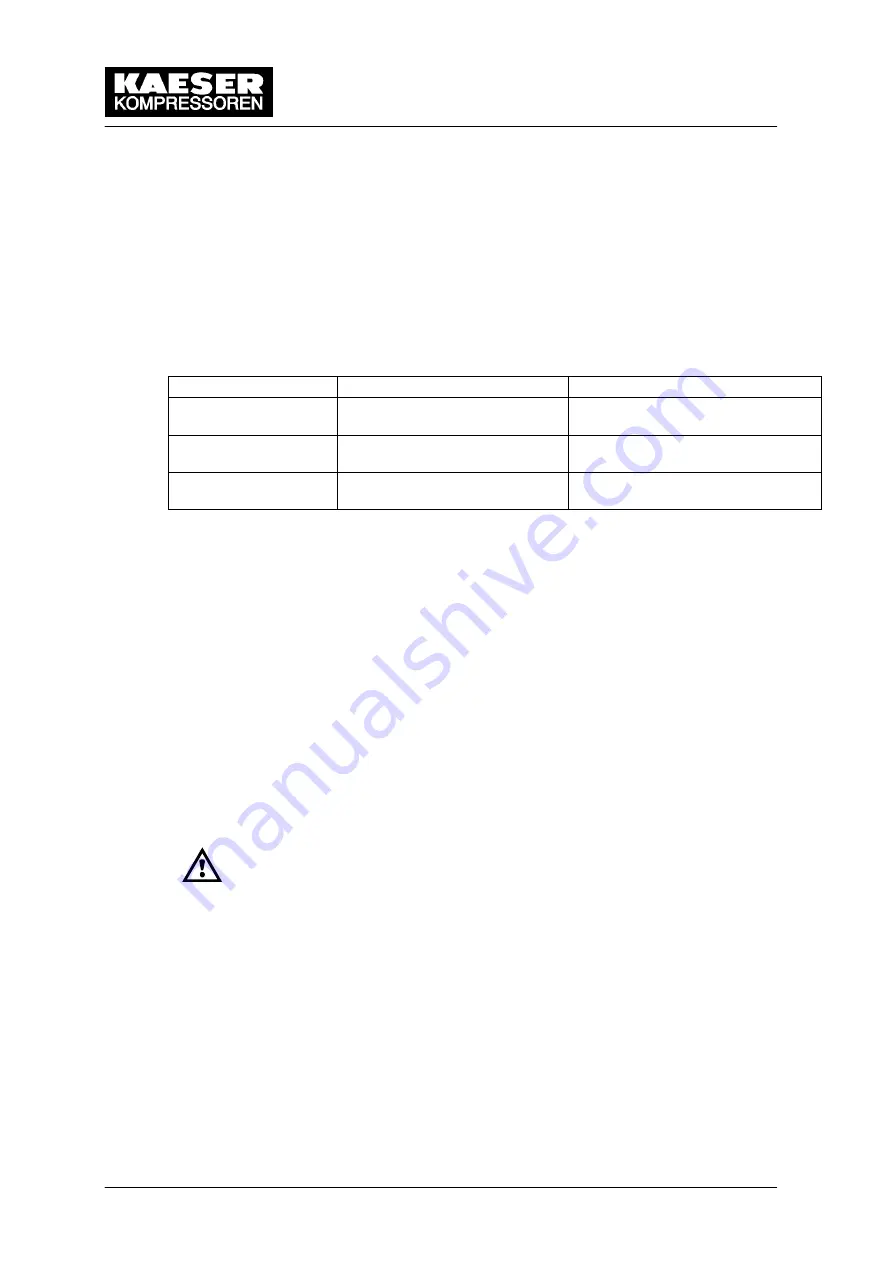

Inspection schedule in accordance with operating safety regulations and with the

strictest according to §15.

Inspection

Schedule

Inspecting authority

Installation and equip-

ping

before initial start ---up

approved supervisory board

Internal inspection

every 5 years after installation or

the last inspection

approved supervisory board

Strength test

every 10 years after installation

or the last inspection

approved supervisory board

Tab. 27

Inspection schedule for Germany

3.4

Safety Devices

Do not change, bypass or disable safety devices.

Do not remove or obliterate labels and notices.

Ensure that labels and notices are clearly legible.

More information on safety devices is contained in chapter 4 ’Design and Function’, sec-

tion 4.4 ’Safety Devices’.

3.5

Hazards

Fundamentals: observe the accepted safety regulations

Observe safety regulations at all times when working on the machine.

Examples of these are directives and national regulations concerning safety and accident

prevention.

3.5.1

Danger from electric current

Electric shock can kill!

Touching electrically live components can cause serious injury or death.

Isolate completely from the mains supply (all conductors)

(switch off at the main isolator)

Ensure the supply cannot be switched on again (lock off).

Check that no voltage is present.

Only work on electrical components when they are voltage---free.

Work carefully.

Before switching on again ensure that:

no one is working on the machine,

all panels are in place and secured,

all access doors are closed.

DANGER

Summary of Contents for CSD 82

Page 2: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ...Appendix 13 83 13 2 2 Pipeline and instrument flow diagram option C1...

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......

Page 96: ......

Page 97: ...Appendix 13 89 13 2 3 Dimensional drawing 13 2 3 1 Air cooling option K1...

Page 98: ......

Page 99: ......

Page 100: ...Appendix 13 92 13 2 3 2 Water cooling option K2...

Page 101: ......

Page 102: ......

Page 103: ...Appendix 13 95 13 2 4 Electrical diagram...

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......