Maintenance

10 --- 51

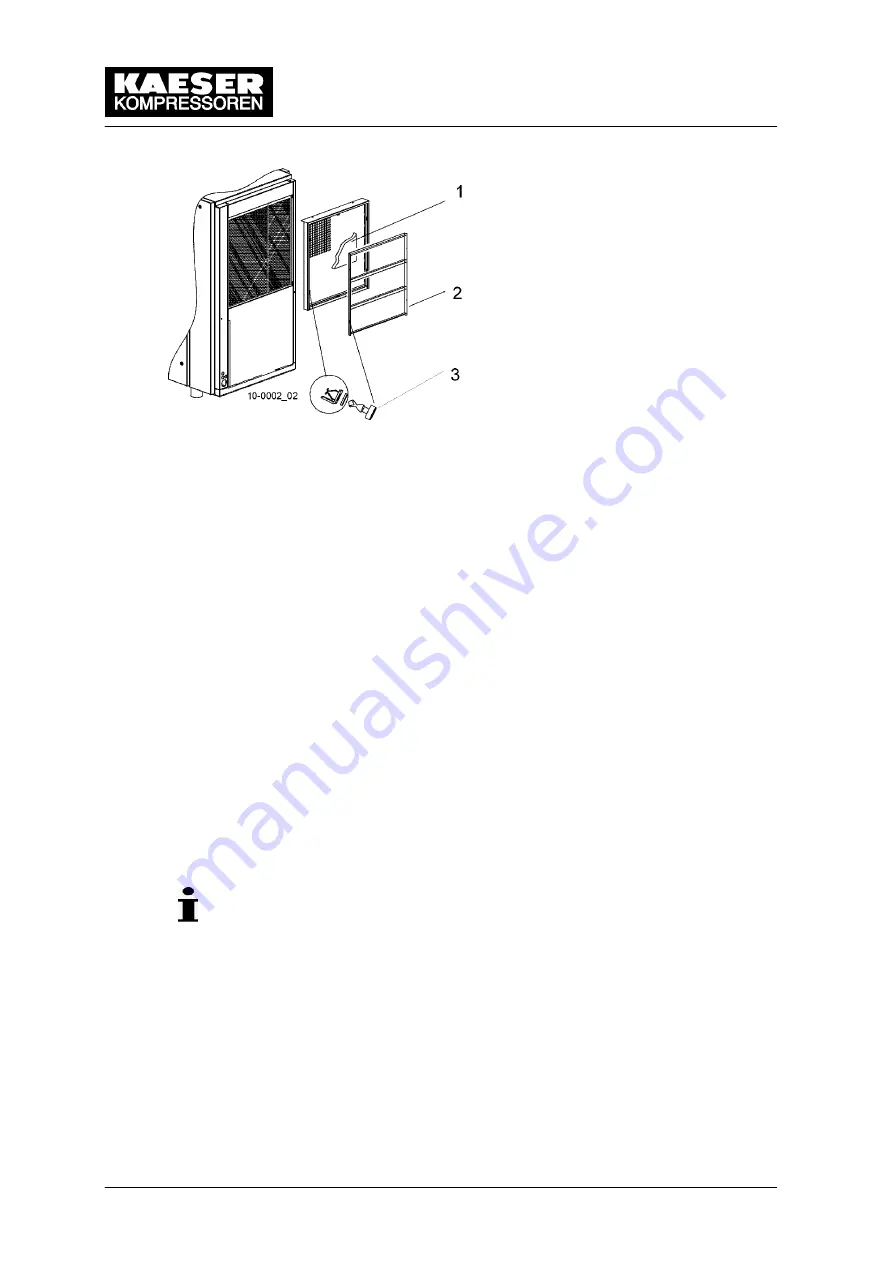

Fig. 18

Cooler filter mats

1

Filter mat

2

Retaining frame

3

Fixing

Removal

Unlock the fixings (3).

Use a screwdriver to turn the fixing 90˚ anti ---clockwise.

Remove the frame (2).

Cleaning

Beat the mat (1) or use a vacuum cleaner to remove loose dirt. If necessary, wash the

mat in lukewarm water and household detergent then rinse thoroughly.

Renew the mat if cleaning is not possible of has already been carried out five times.

Replacing

Replace the frame and close the fixings.

Press and turn the fixings 90˚ clockwise until they latch.

10.3.3

Water cooling maintenance (option K2)

Pre --- condition: Machine switched off.

Mains isolator locked off

Machine cooled down.

Check the cooler regularly for leaks and contamination. Frequency of checking is depend-

ant on the characteristics of the cooling water.

Contamination causes overheating and machine damage.

Observe the airend discharge temperature to detect any tendency to rise.

Cleaning:

An authorised KAESER service agent should clean the cooler when the airend dis-

charge temperature is 10 ˚ C above the annual average.

Leakage

Pressure in the cooling oil circuit is generally higher than that in the cooling water system.

If a leak occurs, oil will run into the cooling water.

Check the cooler visually for leaks.

Have an authorised KAESER service agent check the cooler for internal leaks at least

once a year.

Summary of Contents for CSD 82

Page 2: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ...Appendix 13 83 13 2 2 Pipeline and instrument flow diagram option C1...

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......

Page 96: ......

Page 97: ...Appendix 13 89 13 2 3 Dimensional drawing 13 2 3 1 Air cooling option K1...

Page 98: ......

Page 99: ......

Page 100: ...Appendix 13 92 13 2 3 2 Water cooling option K2...

Page 101: ......

Page 102: ......

Page 103: ...Appendix 13 95 13 2 4 Electrical diagram...

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......

Page 113: ......

Page 114: ......

Page 115: ......

Page 116: ......

Page 117: ......

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......