PRELIMINARY

Subject

to

Revision

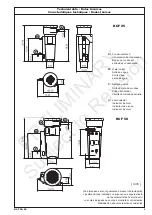

KCF 25, 50

20

Procedure

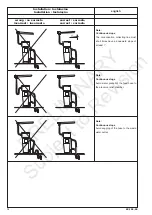

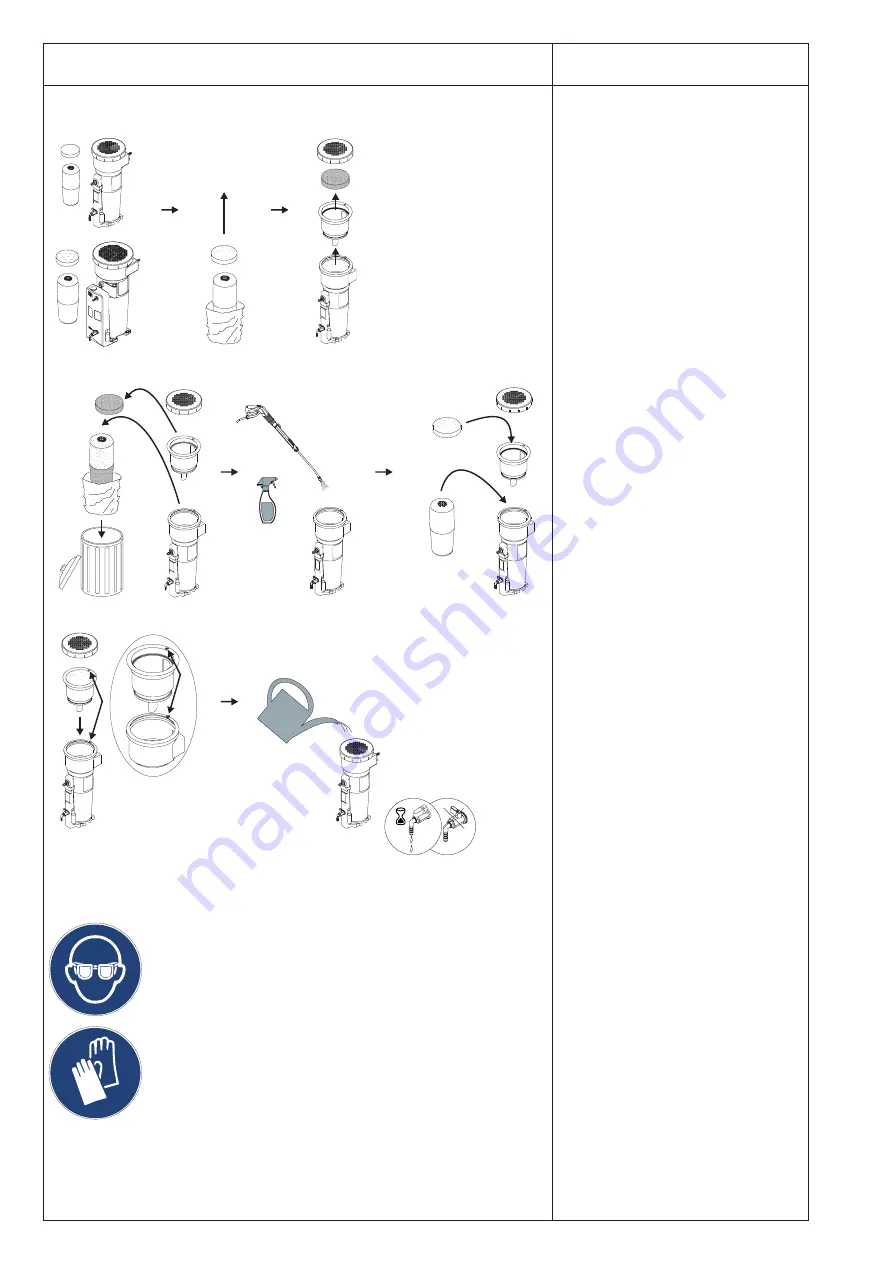

• Step 1. Place new filter set near the

unit. Keep the plastic bag of the new

cartridge for wrapping up the old one.

• Step 2. Shut off the condensate feed

to the unit.

• Step 3. Remove the KCF lid (black cap),

remove filter mat

• Step 4. Remove the Inlet pipe

• Step 5. Lift the old cartridge for the

main tank and allow it to drain. Once

the cartridge has drained place it in

the plastic bag and dispose of the unit

according to your local regulations.

• Step 6. Thoroughly clean the main tank

area with non-abrasive and surfactant-

free cleaner

• Step 7. Insert new cartridge in main

container.

• Step 8. Re-install the inlet pipe and align

the notch on the lid, once inlet pipe is

install insert new filter mat.

• Step 9. Re-install lid (black cap)

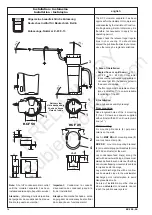

• Step 10. MUST BE COMPLETED

before introducing compressed air

condensate to unit. Pour water into unit

from the top through the pressure relief

chamber area.

• Step 11. Stop poring the water (approx.

1 gallon for the KCF 25 & 3 gallons for

the KCF 50) when it starts to come out

at the water outlet that is located on the

side of the unit.

• Step 12. Wait approximately 5 mins

so the cartridge will adsorb some of

the water & add additional water to the

unit until you see water coming out of

the outlet again. Once this has been

accomplished the unit will be recharged

and ready for full operation.

• Step 13. You know can introduce

condensate into unit via the inlet hose

connector on side.

english

Maintenance • Mantenimiento

Entretien • Manutenção

*

1 EWC 150202 =

European waste disposal key

Código de residuos europeo

Code européen de déchet

Europese afvalsleutel

*2 EWC 13 08 02 =

European waste disposal key

Código de residuos europeo

Code européen de déchet

Europese

afvalsleutel

H

2

O