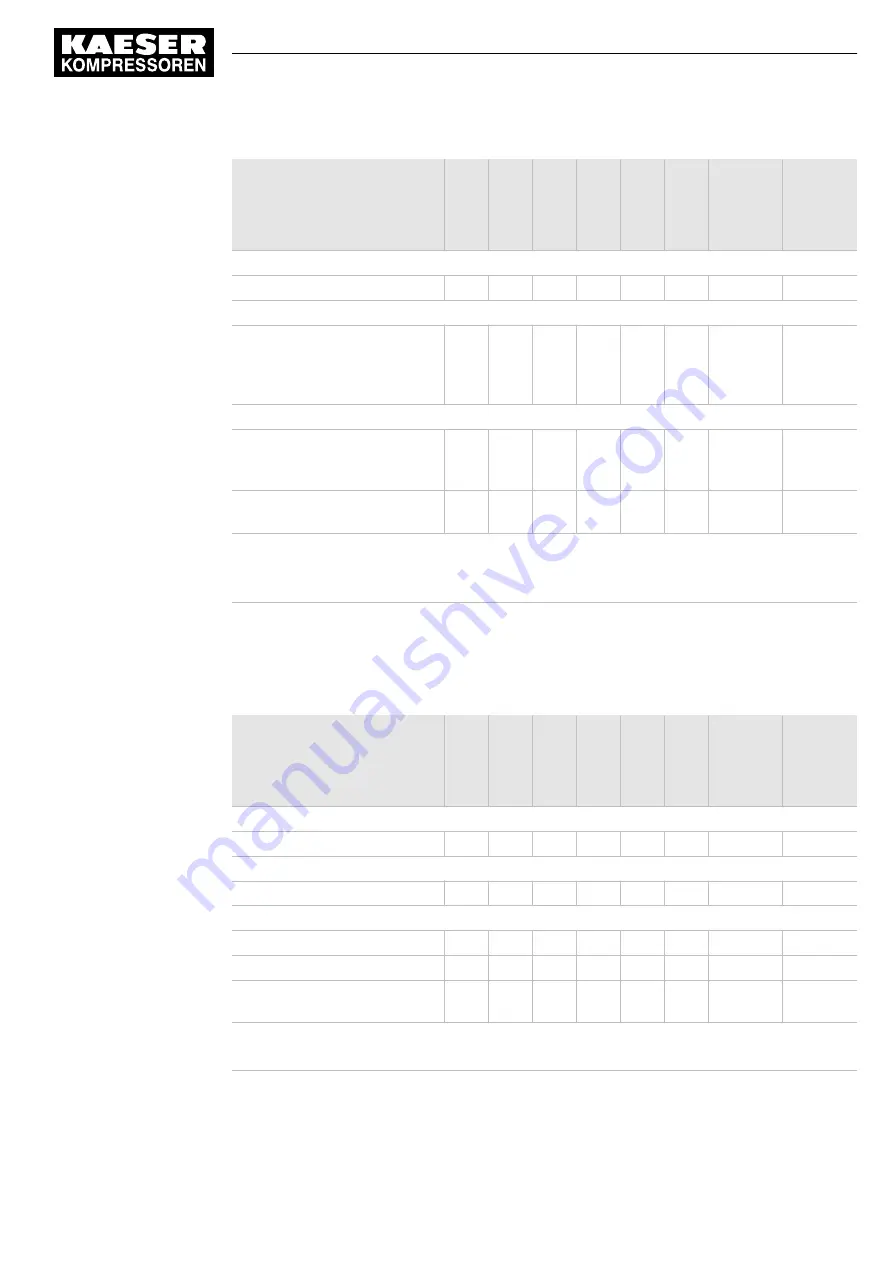

Assembly:

Task

Daily

A250

A500

A1000

A1500

A3000

See Chapter

Note

Bodywork/chassis:

Have lifting eye checked.

X

KS; SW

Pipes and hose lines (fuel hoses, pressure hoses):

(3)

Check all pipes and hose

lines on the machine are tightly

fitted and without leaks or wear;

replace if necessary.

X

KS; SW

Other maintenance tasks:

Check all accessible screw fit‐

tings, lines and clamps on ma‐

chine for wear and tightness.

X

Check all electrical connections

for tightness.

X

KUBOTA = Is serviced by a representative from the engine manufacturer (Kubota Corporation)

KS = Contact KAESER SERVICE; SW = Contact Specialist Workshop

DPF = Diesel Particulate Filter

Tab. 72 Regular machine maintenance tasks

10.3.3.2 Options maintenance schedule

➤ Carry out maintenance tasks according to the following schedule:

Option:

Task

Daily

A250

A500

A1000

A2000

A20000

See chapter

Note

Option da - Compressed air aftercooler:

Clean cooler.

X

Option da – Water separator:

Clean and check the dirt trap.

X

Option dd – Filter combination:

Drain condensate.

X

Change the filter elements.

X

Replace seal of filter element

(*).

X

EL = Qualified electrician

KS = Contact KAESER SERVICE; SW = Contact specialized workshop

Tab. 73 Regular maintenance tasks for options

10 Maintenance

10.3 Following the maintenance plans

No.: 902366 10 USE

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M55 PE SIGMA CONTROL SMART pV

99