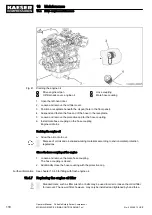

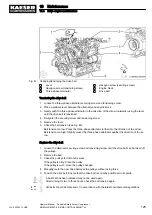

Fig. 47 Changing/tensioning the drive belt

1

Lever

2

Hexagon screw (tensioning screw)

3

Three-phase alternator

4

Hexagon screw (securing screw)

5

Engine block

6

Drive belt

Tensioning the drive belt

1. Loosen the three-phase alternator securing screw and tensioning screw.

2. Place a suitable lever between the alternator and engine block.

3. Gently push the three-phase alternator in the direction of the arrow (outwards) using the lever

until the drive belt is tensioned.

4. Re-tighten the securing screw and tensioning screw.

5. Remove the lever.

6. Check the belt tension (see Fig. 46).

Belt tension too low: Press the three-phase alternator further into the direction of the arrow.

Belt tension too high: Slightly swivel the three-phase alternator against the direction of the ar‐

row.

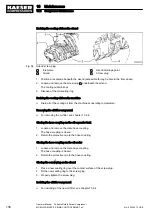

Replace the drive belt

1. Loosen the alternator securing screw and tensioning screw until the drive belt can be taken off

the pulleys.

2. Remove the belt.

3. Check the pulleys for dirt and/or wear.

If the pulley is dirty: Clean the pulley.

If the pulley is worn: Have the pulley changed.

4. Manually route the new drive belt over the pulleys without using force.

5. Tension the drive belt. Ensure that the drive belt is correctly positioned in its guide.

A belt that has been replaced may not be used again.

After running for two to three hours, check the belt tension again.

Old belts should be disposed of in accordance with the latest environmental regulations.

10 Maintenance

10.4 Drive engine maintenance

No.: 902366 10 USE

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M55 PE SIGMA CONTROL SMART pV

125