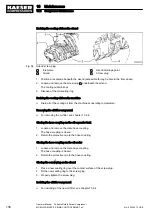

Starting the machine and performing a test run

1. Switch on machine by using the «START» key on the control panel of

SIGMA CONTROL SMART.

2. Let machine warm up in IDLE mode.

Warm-up has been successful when required discharge temperature has been reached.

3. Press and hold the «OFF» key on the control panel of SIGMA CONTROL SMART for more

than 1 second.

The machine is switched off.

4. Wait until the machine has automatically vented.

Pressure gauge reads 0 psig!

5. Open the discharge valves.

6. Open the left-hand door.

7. After approximately 5 minutes: Check the cooling oil level.

Cooling oil level too low.

➤ Top off the cooling oil again.

8. Visually inspect for leaks.

9. Close the door.

Dispose of old cooling oil and any materials or parts contaminated with oil according to envi‐

ronment protection regulations.

Resetting maintenance timer

➤ Reset the maintenance timer as described in the separate User Manual of

SIGMA CONTROL SMART, chapter “Reset maintenance timer”.

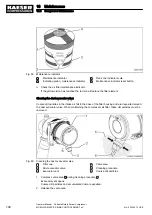

10.6.5 Oil separator tank dirt trap maintenance

The control valve is mounted on the oil separator tank cover. The control valve has two different

dirt traps that must be cleaned at least once a year.

Material Cleaning cloth

Wrench

Small screwdriver

Maintenance kit, control valve

Petroleum ether or spirit

Precondition The machine is switched off and has cooled down.

Air consumers are disconnected,

the outlet valves are open,

the machine is fully vented, the pressure gauge reads 0 psig!

Left door is open, «Controller ON/OFF» switch is switched off,

the minus cable of the battery has been disconnected.

10 Maintenance

10.6 Compressor Maintenance

142

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M55 PE SIGMA CONTROL SMART pV

No.: 902366 10 USE