2. For determining the defined torque, see chapter 2.4.2.

3. Tighten all screw connections with the defined torque.

10.8.2 Specific guideline values for tightening torques

Screw connections for components that are either safety-related or under particular stress must be

tightened with specific tightening torques.

Examples:

■ For details of specific tightening torques, see chapter 2.4.2.

─ E.g. Screw connections on lifting eyes.

─ E.g. Cover screws on the oil separator tank.

■ Values for further specific tightening torques are provided in the section covering the relevant

maintenance task.

Damage to the machine from insufficient clamping force at screw connections

➤ Screw connections for components that are either safety-related or under particular

stress must be tightened exclusively with the correct specific tightening torque.

1. Determine the correct specific tightening torque.

2. Tighten the screw connections with the specific tightening torque.

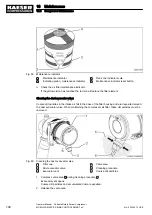

10.8.3 Sealed screw connections

Screw connections which must not be adjusted are sealed with a colored locking varnish.

Damage to the machine caused by adjusting the settings

➤ Leave sealed screw connections in their original condition.

➤ Do not loosen or adjust sealed screw connections.

Failure to comply with these instructions will invalidate all warranty claims.

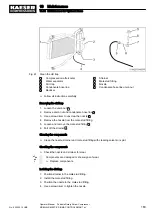

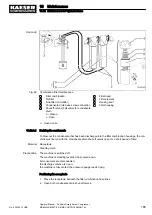

10.9 Check wing doors

The machine's closed wing doors fulfill the following functions during the machine's operation:

Protection against contact, cooling air flow, sound proofing and weather protection.

In order to ensure these functions at any time, the wing doors and its connecting elements

must always be in a perfect condition.

Overview:

■ Maintain rubber sealing strips

■ Check closed wing doors

■ Check connecting elements

10 Maintenance

10.9 Check wing doors

No.: 902366 10 USE

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M55 PE SIGMA CONTROL SMART pV

155