Affected by temperature, atmospheric oxygen and time, these biodiesel components in the fuel

may decompose in the fuel and thus cause damages within the fuel system.

The fuel must be filtered before it is filled into the machine when it has been supplied in bar‐

rels or canisters. This procedure prevents malfunctions in the fuel system caused by contami‐

nation.

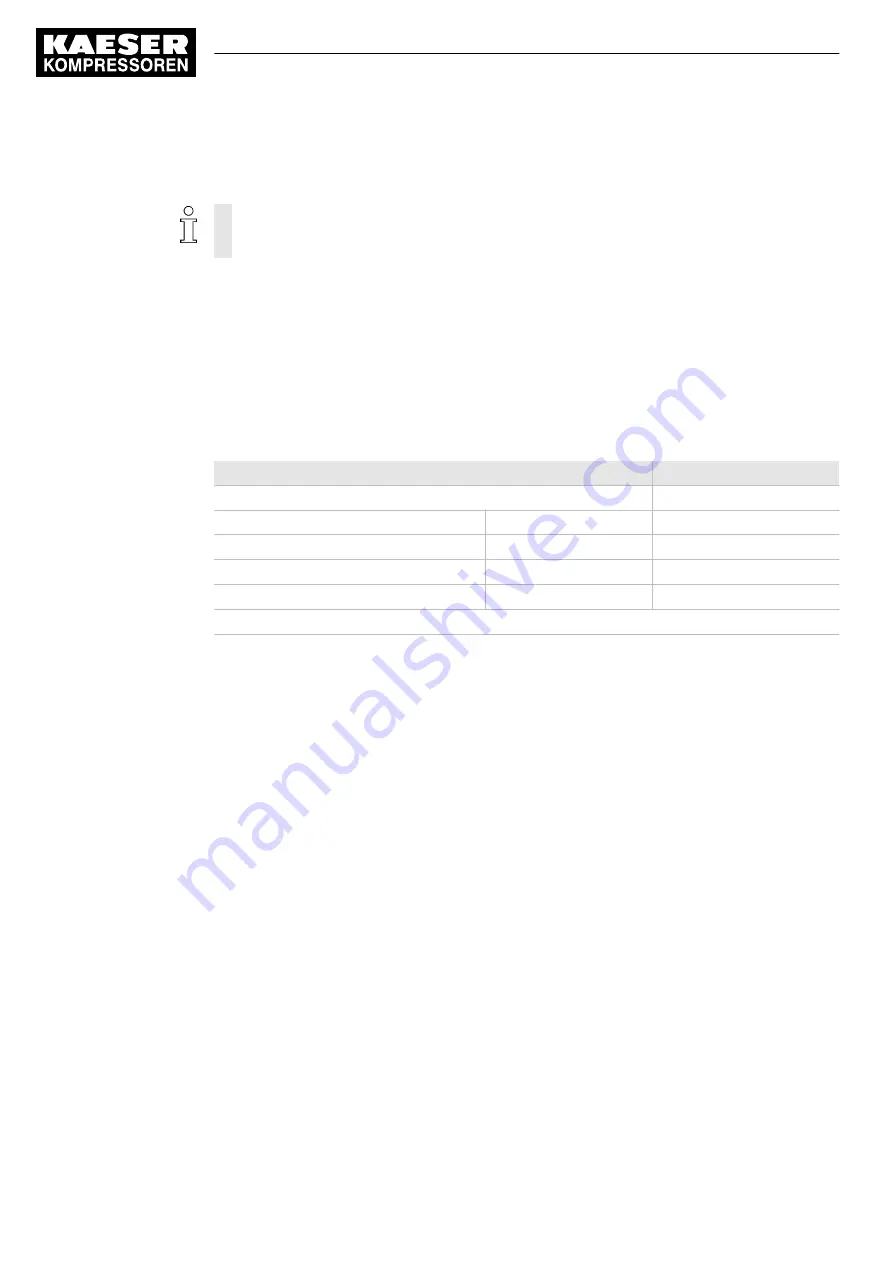

2.8.4 Engine coolant recommendation

In fluid-cooled engines, the cooling fluid must be treated and monitored to prevent engine damage.

Water quality:

An important factor in the treatment of cooling fluid is the correct water quality.

As a rule, clear, clean fresh water must be used, which should be as soft as possible and in ac‐

cordance with the following analytical values:

Feature

Value

pH value

6.5-8.0

Chloride

[mg/l]

Max. 80

Ch sulfate

[mg/l]

Max. 160

Alkaline ground ions

mmol/l

2.7

Hardness

°dH

15

1°dH = 0.1783 mmol/l; alkaline ground ions = 7.147 mg/l Ca

2+

or 4.336 mg/l Mg

2+

Tab. 32 Water quality specification

Contact the local water utilities for information regarding water quality. If the water does not meet

the above parameters, it must be treated.

If suitable water is not available, distilled or demineralized water should be used for treating the

coolant. Seawater, brackish water, brine and industrial wastewater are not suitable. Salts may

cause corrosion or the formation of disruptive residues.

Coolant quality:

In the course of ongoing technical development, a new corrosion inhibitor/antifreeze has been ap‐

proved by the engine manufacturer.

This features the following advantages over the corrosion inhibitors/antifreeze that was approved

previously:

■ Less residue in the engine cooling system

■ Improved heat flow

■ Improved environmental compatibility

The coolant (cooling fluid) is treated by the addition of anti-freeze with ethylene glycol-based anti-

corrosion additives to the water.

The coolant used must be in accordance with the stipulations provided by the engine manufacturer

KUBOTA.

2

Technical Data

2.8

Engine

16

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M55 PE SIGMA CONTROL SMART pV

No.: 902366 10 USE