3.4.3 Complying with inspection schedules and accident prevention regulations

The machine is subject to local inspection schedules.

➤ Have the pre-commissioning inspection carried out according to the Ordinance on Industrial

Safety and Health, §15.

➤ Carry out recurring inspections:

The user must ensure that the machine's safety devices are checked for function as required

or at least annually.

➤ Carry out oil changes:

The user must ensure that the cooling oil is changed as required or at least annually and the oil

change must be documented. Intervals may be varied if an analysis proves that the oil is still

usable.

➤ Keep to inspection intervals in accordance with the Ordinance on Industrial Health and Safety

with maximum intervals as laid down in §16:

Inspection

Inspection interval

Inspection authority

Equipment inspec‐

tion

Before commissioning

Approved supervisory body.

Internal inspection Every 5 years after commissioning

or the last inspection

Contact an authorized KAESER serv‐

ice representative.

Strength test

Every 10 years after commissioning

or the last inspection

Contact an authorized KAESER serv‐

ice representative.

Tab. 39 Inspection intervals according to Ordinance on Industrial Health and Safety

Checking the lifting point

The user is responsible for ensuring that the machine's lifting point and fixings are inspected ac‐

cording to national regulations for wear and damage.

➤ Have lifting point checked.

Lifting point is not in order: The machine must not be transported by crane. Have the machine

repaired immediately.

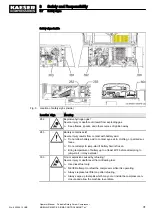

3.5 Dangers

Basic instructions

The following describes the various forms of danger that can occur during machine operation.

Basic safety instructions are found in this service manual at the beginning of each chapter in the

section entitled 'Safety'.

Warning instructions are found before a potentially dangerous task.

3.5.1 Safely dealing with sources of danger

The following describes the various forms of danger that can occur during machine operation.

Exhaust fumes

Exhaust gases from combustion engines contain carbon monoxide, a color- and odorless but high‐

ly toxic gas. The inhalation of minute quantities can be lethal.

3

Safety and Responsibility

3.5

Dangers

No.: 902366 10 USE

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M55 PE SIGMA CONTROL SMART pV

21