Compressed air quality

The composition of the compressed air must be suitable for the actual application in order to pre‐

clude health and life-threatening dangers.

➤ Use appropriate systems for air treatment before using the compressed air from this machine

as breathing air (fresh air reinforcement) and/or for the processing of foodstuffs.

➤ Use food grade cooling oil whenever compressed air is to come into contact with foodstuffs.

Spring forces

Springs under tension or compression store energy. Uncontrolled release of this energy can cause

serious injury or death.

Minimum pressure check valves, safety relief valves and inlet valves are powerfully spring-loaded.

➤ Do not open or dismantle any valves.

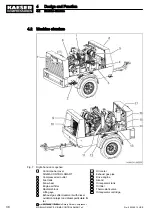

Rotating components

Touching the fan wheel, the coupling or the belt drive while the machine is switched on can result

in serious injury.

➤ Do not open the service doors or panels while the machine is running.

➤ Prior to opening the service doors or the enclosure, switch off the engine, disconnect from

power source and secure against unintended reactivation.

➤ Wear close-fitting clothes and a hair net if necessary.

➤ Ensure that all covers and safety guards are in place and secured before re-starting.

Temperature

The operation of the combustion engine and the compression generate high temperatures. Touch‐

ing hot components may cause injuries.

➤ Avoid contact with hot components.

These include combustion engine, airend, oil and compressed air lines, coolers and oil separa‐

tor tank. Any objects in or near the flow of exhaust gas or discharged cooling air will become

very hot.

➤ Wear protective clothing.

➤ Wear protective gloves when connecting or disconnecting external compressed air hoses to

the outlet valves.

➤ Allow the machine to cool down before commencing any maintenance work.

➤ If welding is carried out on or near the machine, take adequate measures to prevent sparks or

heat from igniting oil vapors or parts of the machine.

Noise

The enclosure absorbs the machine noise to a tolerable level. This function will be effective only if

the body is closed.

➤ Operate the machine only with closed body.

➤ Check machines that are lined with sound insulation material for perfect condition of the sound

insulation material.

➤ Wear ear protection if necessary.

Safety relief valve blow-off results in high noise emission.

➤ Never generate compressed air without consumers being connected.

3

Safety and Responsibility

3.5

Dangers

No.: 902366 10 USE

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M55 PE SIGMA CONTROL SMART pV

23