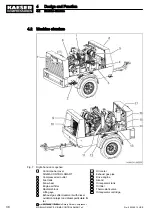

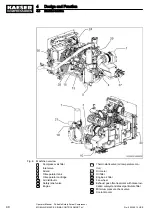

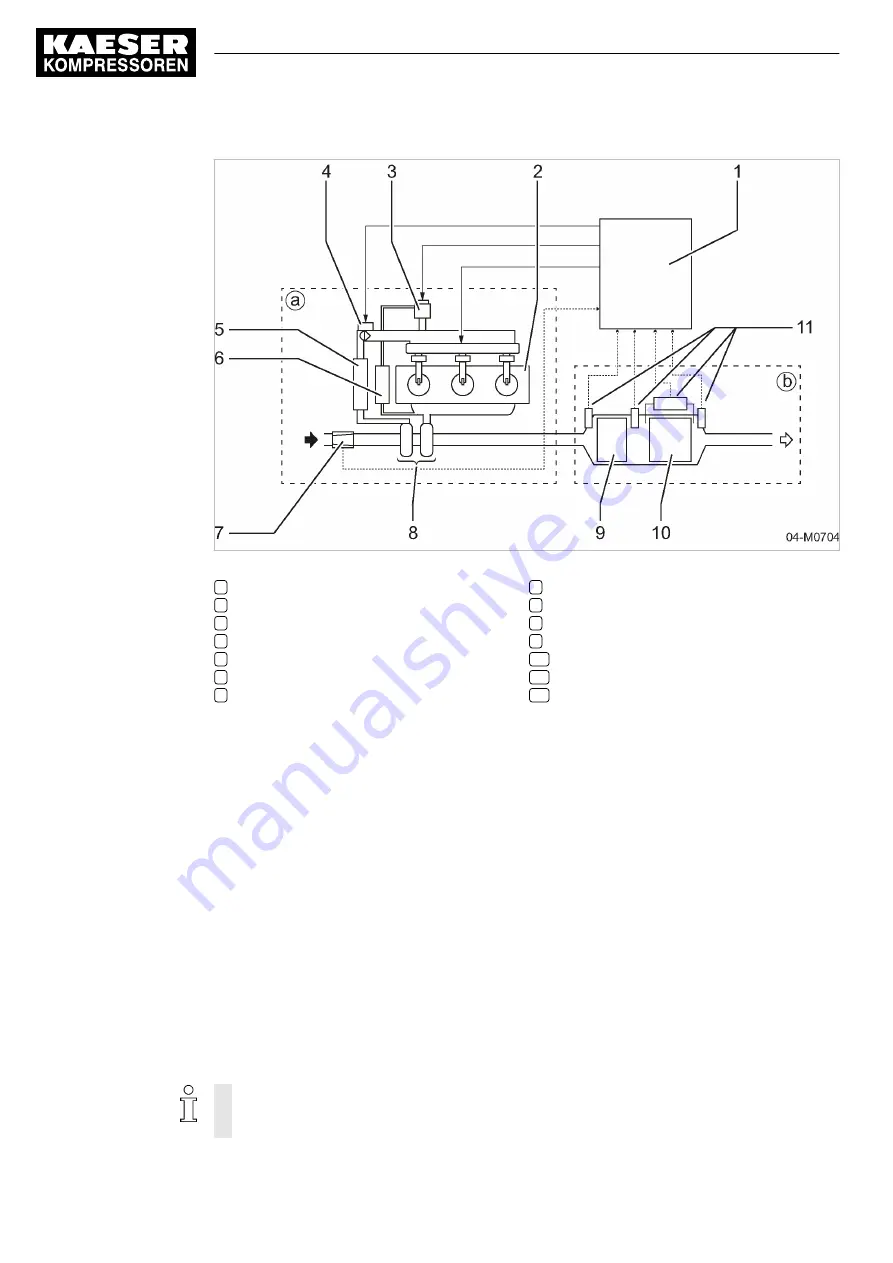

Fig. 10 Principle of treatment devices

1

Engine control unit (ECU)

a

Common rail system

2

Engine block

3

Exhaust gas return valve (EGR)

4

Inlet throttle

5

Intercooler

6

Cooler exhaust gas return (EGR)

7

Air flow meter

8

Turbocharger

b

Exhaust gas treatment system

9

Diesel oxidation catalytic converter (DOC)

10

Diesel particulate filter (DPF)

11

Sensors

12

SIGMA CONTROL SMART controller

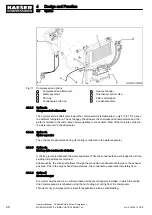

Diesel oxidation catalytic converter (DOC)

The diesel oxidation catalytic converter uses the fuel which has not been burnt during final injection

for the active regeneration of the diesel particulate filter. The diesel oxidation catalytic converter

serves a source of heat for the regeneration of the diesel particulate filter.

Diesel particulate filter (DPF)

The diesel particulate filter is used for reducing the particulates present in the diesel engine ex‐

haust (fine solids and mostly soot). Nearly all of these particles are trapped in the filter and burnt to

CO

2

at high exhaust gas temperature.

At a low exhaust gas temperature when the particulates do not burn spontaneously, a pressure dif‐

ference occurs between inlet and outlet of the diesel particulate filter. This initiates a regeneration

of the filter, during which the soot is removed. Regeneration is activated when the filter medium is

saturated with soot to a certain degree.

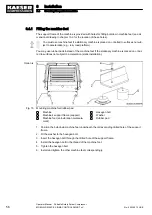

4.8.3 Regeneration of the diesel particulate filter

The removal of soot from the diesel particulate filter is called regeneration.

As a rule, the engine control unit (ECU) automatically starts the regeneration. Regeneration

must be manually initiated (parked regeneration) only in exceptional cases (adverse applica‐

tion conditions).

4

Design and Function

4.8

Exhaust gas after-treatment

46

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M55 PE SIGMA CONTROL SMART pV

No.: 902366 10 USE