Fig. 33 Cleaning the primary filter element

1

Cleaning the primary filter element

2

Checking the primary filter element

3

Compressed air gun with blast pipe (bent

to approx. 90° at the end)

4

Primary filter element

5

Flashlight

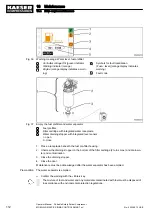

1. Use dry compressed air (<30 psi!) to blow out dirt from the filter element at an angle, from the

inside to the outside.

2. Blow out the primary filter element until no more dust appears.

3. In a darkened room, use a suitable flashlight to shine a light through the cleaned primary filter

element.

The cleaned primary filter element displays no cracks or holes.

The cleaned filter element is in the correct condition.

4. Insert the cleaned and checked primary filter element into the filter housing.

5. Position the filter cap in place.

6. Secure the filter cap with all three retaining clamps.

7. Check to ensure the filter cap is correctly attached.

Dispose of old parts and contaminated materials in accordance with environmental protection

regulations.

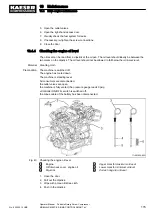

10.4.3 Fuel system maintenance

Make sure no dirt can get into the fuel system during maintenance. Clean components and their

surroundings before disassembling.

Material Spare parts

Receptacle

Cleaning cloth

Precondition The machine is switched off.

The machine is standing level.

Air consumers are disconnected,

the outlet valves are open,

the machine is fully vented, the pressure gauge reads 0 psig.

The machine has cooled down.

«Controller ON/OFF» switch is switched off, the minus cable of the battery has been disconnected.

10 Maintenance

10.4 Drive engine maintenance

No.: 902366 10 USE

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M55 PE SIGMA CONTROL SMART pV

109