5. Remove the dipstick once more and read off the oil level.

The oil level is between the upper and the lower mark: The oil level is in the correct range.

The level has reached the lower mark

minimum level or is below the mark: Replenish engine

oil.

6. Close the door.

The marked

maximum oil level should not be exceeded in order for the level of oil in the

crankcase not to reach the crankshaft. If this were to occur, it could create oil bubbles that

would reduce the oil's lubricating capability and impair engine performance.

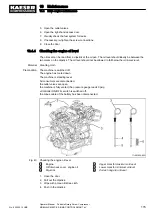

10.4.5 Engine oil filling and topping off

Material New engine oil, see chapter 2.8.5 for drive engine filling quantity.

Cleaning cloth

Funnel

Precondition The machine is switched off.

The machine is standing level.

Air consumers are disconnected,

the outlet valves are open,

the machine is fully vented, the pressure gauge reads 0 psig.

«Controller ON/OFF» switch is switched off, the minus cable of the battery has been disconnected.

Filling with engine oil

Pay attention to the «maximum oil level» mark on the oil dipstick.

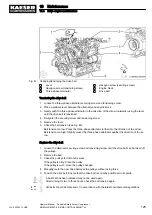

1. Open the left-hand door.

2. Loosen and remove the oil filler cover.

3. Fill with fresh engine oil.

It takes a few minutes for oil to reach the sump.

4. Wait for at least 5 minutes.

5. Check the oil level.

Low oil level: Replenish engine oil.

6. Replace the plug in the filler port.

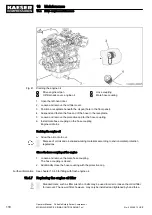

Preparing for operation

1. Connect the negative battery terminal.

2. Switch on the «Controller ON/OFF» switch.

3. Close the door.

Starting the machine and performing a test run

1. Switch on machine by using the «START» key on the control panel of

SIGMA CONTROL SMART.

2. Warm-up machine by letting it run in IDLE mode.

10 Maintenance

10.4 Drive engine maintenance

116

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M55 PE SIGMA CONTROL SMART pV

No.: 902366 10 USE