➤ Check the correct fuel type and fuel specifications by referring to Table 49.

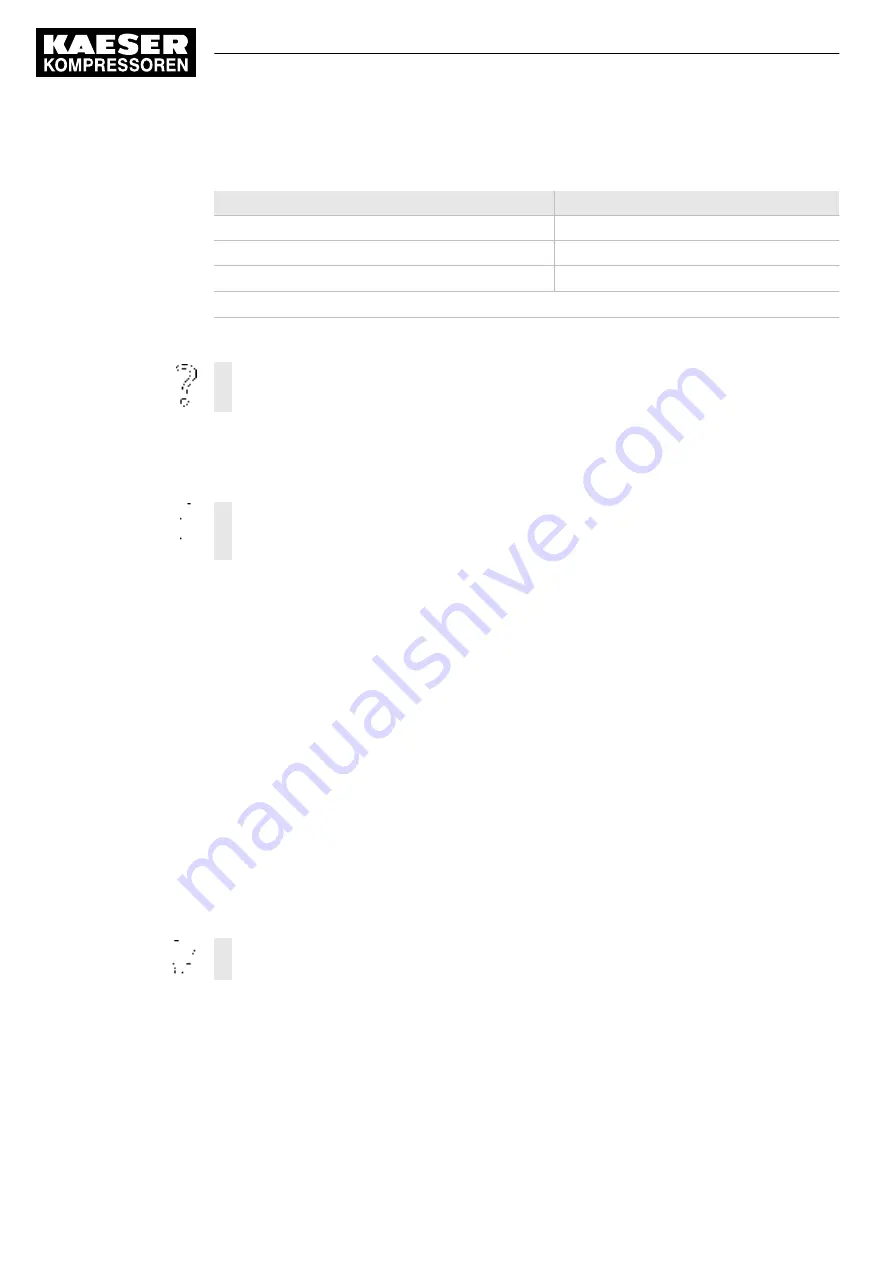

Fuel type / fuel specification

Designation / Standard

Fuel type

Diesel fuel

Recommended fuel specification

EN 590

(1)

Recommended fuel specification

ASTM D975

(2)

(1)

≙ Sales region Europe,

(2)

≙ Sales region USA

Tab. 49 Fuel / fuel specification

Fuel type / specification does not comply with regulations.

➤ Under no circumstances must the fuel tank be filled with the incorrect fuel type.

Further information For more details on the correct fuel specification, see Chapter 2.6.3.

8.3.2 Filling the fuel tank at a pump by means of a refueling nozzle

Liquid fuels expand at high ambient temperatures. To avoid overflowing, the fuel tank must

not be filled to the brim.

The

maximum fill level is indicated on the fuel tank.

Precondition The machine is standing level.

The machine has cooled down.

The enclosure is open.

All compressed air consumers are disconnected,

the discharge valves are open,

the machine is fully vented, the pressure gauge reads 0 psig.

The negative cable to the battery is disconnected.

The selected fuel meets the requirements specified in Table 49.

1. Loosen and remove the fuel tank cap.

2. Insert the diesel fuel nozzle into the filler port.

3. Activate the fuel nozzle.

Refueling begins.

4. Wait until the maximum fill level of the fuel tank has been reached.

Sufficient expansion volume remains.

5. Shut off and remove the fuel nozzle.

6. Close the filler port with the cap.

Dispose of any spilled fuel and fuel-contaminated working materials in accordance with appli‐

cable environmental regulations.

Preparing for operation

1. Connect the negative cable to the battery.

2. Close the enclosure.

8

Operation

8.3

Refueling the machine

76

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M58utility SIGMA CONTROL SMART

No.: 901779 08 USE