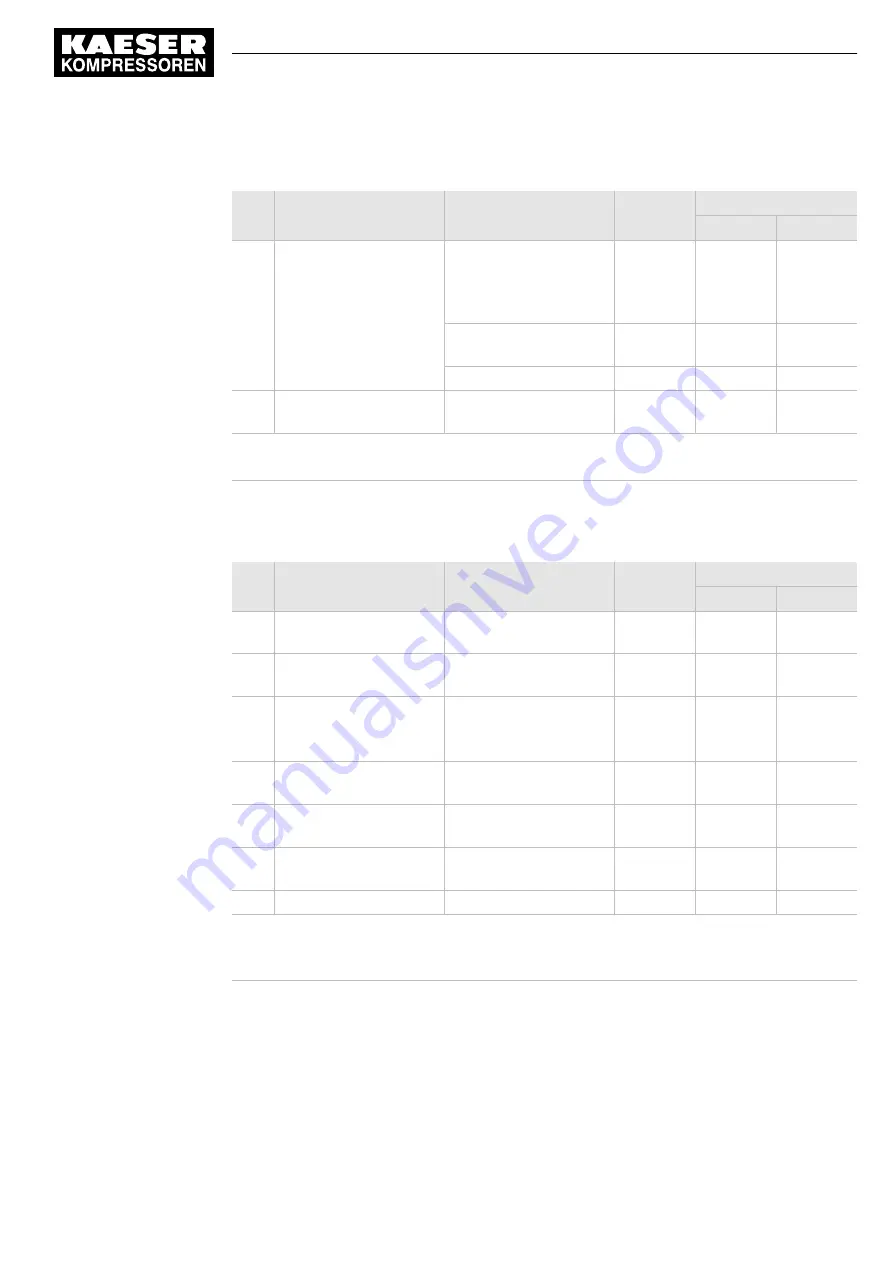

Alarm codes, range 1200 – 1299 “Compressor faults”:

Code Meaning

Remedy

See

chapter

Where can I get help?

SW

KS

1200 Fault - ADT high.

Check operating condi‐

tions.

Allow the machine to cool

down.

–

–

Check the cooling oil lev‐

el.

–

–

Clean the cooler.

–

–

1201 Fault - OST pressure

high.

Have it checked.

–

–

X

SW = specialised workshop; KS = KAESER SERVICE

ADT = Airend discharge temperature; OST - Oil separator cartridge

Tab. 74 Alarm messages and actions concerning the compressor unit

Alarm codes, range 1300 – 1399 “Controller faults”:

Code Meaning

Remedy

See

chapter

Where can I get help?

SW

KS

1300 Fault – PLC memory er‐

ror

Have it checked.

–

–

X

1302 Fault PLC – HMI commu‐

nication.

Have it checked.

–

–

X

1303 Fault PLC – temperature

high.

Check setup conditions.

Allow the machine to cool

down.

–

–

1304 Fault – PLC power sup‐

ply.

Have it checked.

–

–

X

1306 PLC - ECU communica‐

tion fault.

Have checked.

–

–

X

1310 Fault – Fault in Watch‐

dog.

Have it checked.

–

–

X

1311 I/O module fault.

Have it checked.

–

–

X

SW = specialised workshop; KS = KAESER SERVICE

PLC = Programmable logic controller; HMI = Human-machine interface; Watchdog = Function

monitoring; ECU - Motor electronic

Tab. 75 Alarm messages and actions concerning the controller.

9

Fault Recognition and Rectification

9.2

Analysing SIGMA CONTROL SMART messages

No.: 901783 08 USE

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M82 SIGMA CONTROL SMART

101