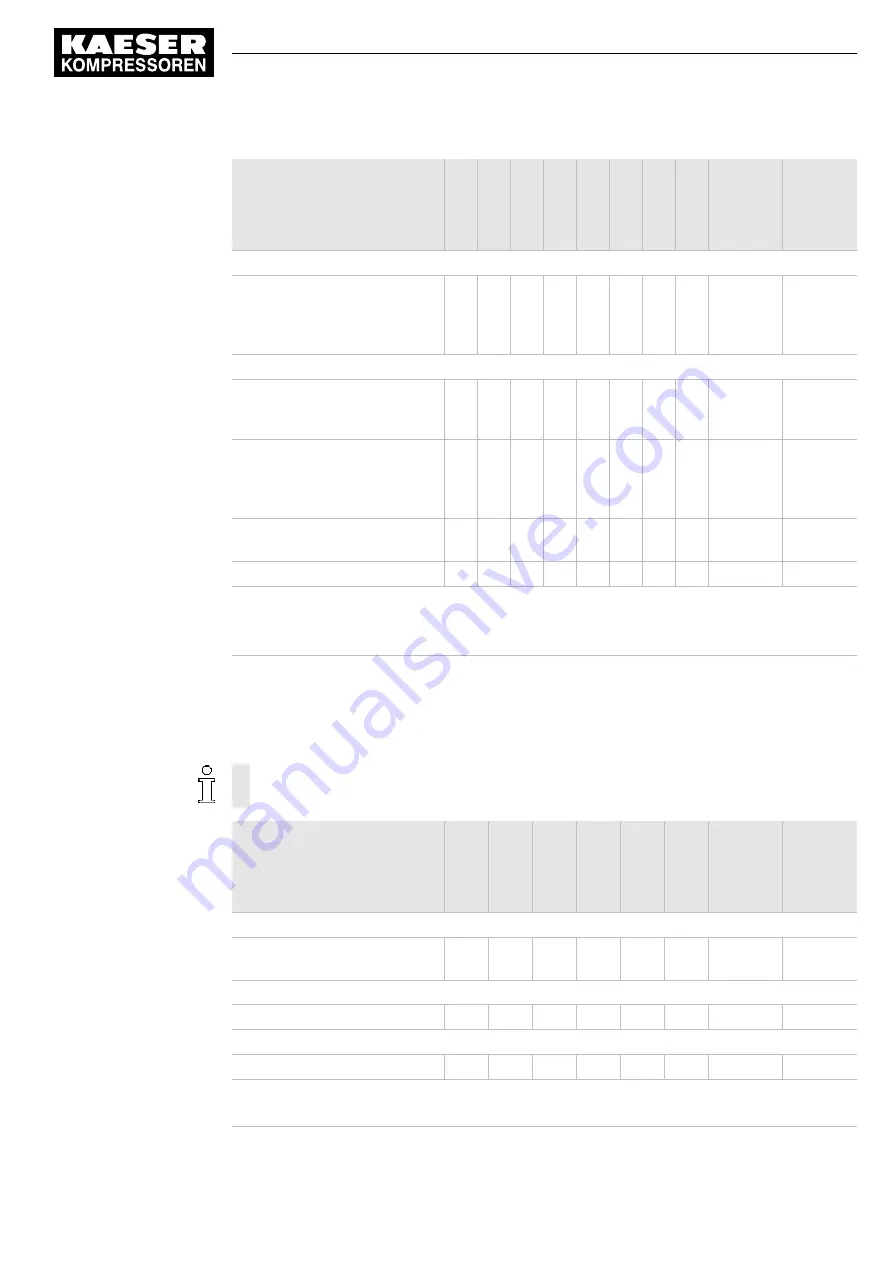

Assembly:

Task

Daily

A250

A500

A1000

A1500

A2000

A3000

A36000

See Chapter

Note

Pipes and hose lines (fuel hoses, pressure hoses):

Check all pipes and hose lines

on the machine are tightly fitted

and without leaks or wear; re‐

place if necessary (**).

X

KS; SW

Further maintenance tasks:

Check engine interior for foreign

substances, remove if necessa‐

ry.

X

Check all accessible screw con‐

nections, pipes and clamps in

machine are securely fitted and

free from wear.

X

Check all electrical connections

for tightness.

X

Check lighting system function.

X

KUBOTA = is serviced by a representative from the engine manufacturer (Kubota Corporation)

KS = Contact KAESER SERVICE; SW = Contact specialised workshop

DPF = diesel particulate filter

Tab. 95 Regular machine maintenance tasks

10.3.4.2 Maintenance schedule options

➤ Carry out maintenance tasks according to the following schedule:

The maintenance work marked with (*) in the tables must additionally be carried out every

6 months if the annual operational performance is more than 500 operational hours.

Option:

Task

Daily

A250

A500

A1000

A2000

A20000

See chapter

Note

Option ea, ec - tool lubricator:

Check the oil level in the tool lu‐

bricator.

X

Option da, df, dc, dd – Centrifugal separator:

Clean and check the dirt trap (*).

X

Options da, df, dc, dd – compressed air aftercooler:

Clean the cooler.

X

EL = qualified electrician

KS = Contact KAESER SERVICE; SW = Contact specialised workshop

10 Maintenance

10.3 Maintenance schedules

No.: 901783 08 USE

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M82 SIGMA CONTROL SMART

117