3. Start the compressor engine.

4. In order to increase the pressure in the exhaust system, partially cover the exhaust discharge

pipe with a fire-proof object.

Soot will drain through the hose into the receptacle.

5. Shut down the engine.

6. Remove the hose and replace the plug.

It is recommended to blow out the spark arrestor with compressed air once a year.

Dispose of soot according to environmental protection regulations.

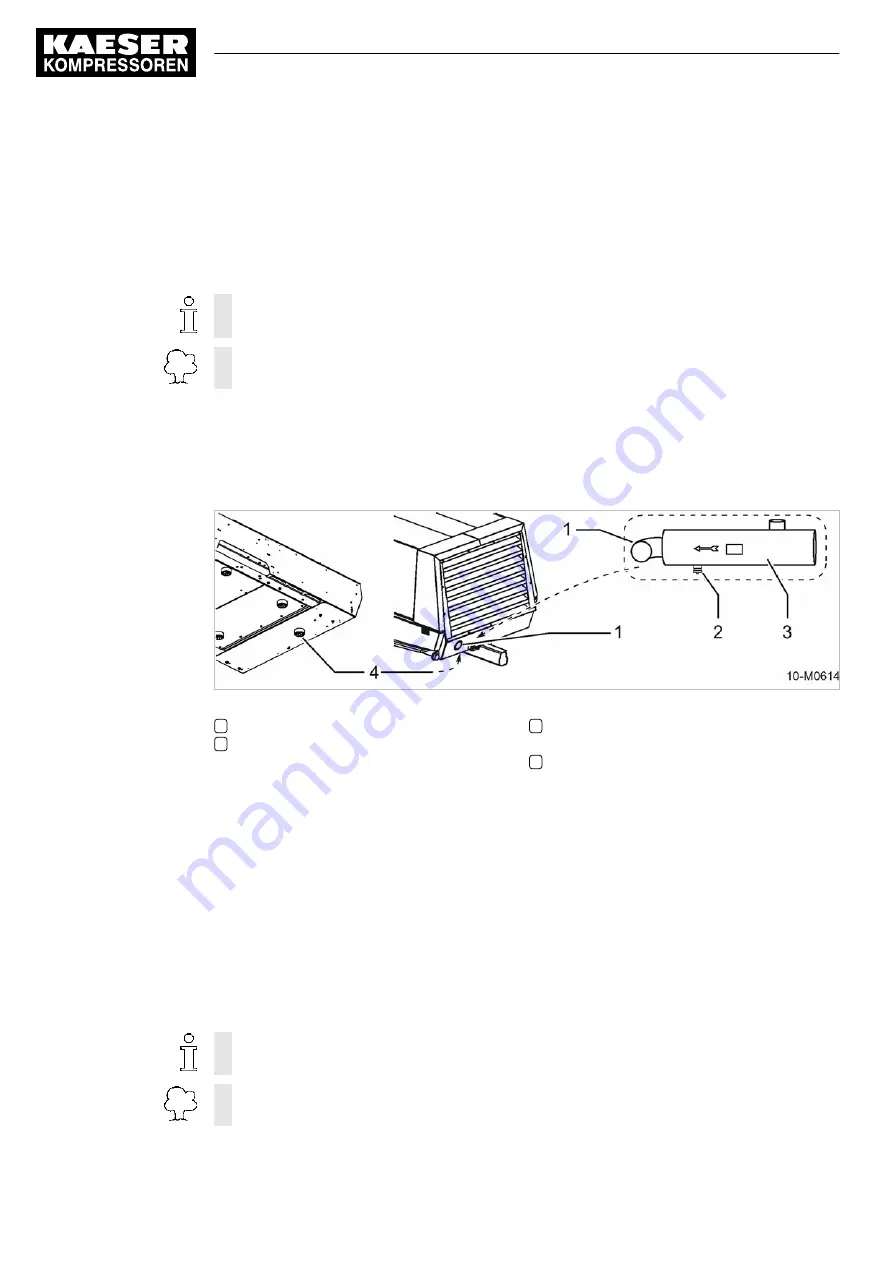

Cleaning the spark arrestor (sealed floor pan)

In machines with a sealed floor pan, the service openings are closed with plugs. In order to access

the port of the soot drain, you must remove the appropriate plug.

Fig. 78 Cleaning the spark arrestor (sealed floor pan)

1

Exhaust silencer end pipe

2

Soot drain port with plug

3

Exhaust silencer with integrated spark ar‐

restor

4

Service opening, closed with plug (access

to drain port)

1. Unscrew the service opening plug.

2. Unscrew the soot drain plug.

3. Push one end of the hose over the drain port and place the other end in the receptacle.

4. Start the compressor engine.

5. In order to increase the pressure in the exhaust system, partially cover the exhaust discharge

pipe with a fireproof covering.

Soot will drain through the hose into the receptacle.

6. Shut down the engine.

7. Remove the hose and replace the plug.

8. Screw the service plug back into the floor pan.

It is recommended to blow out the spark arrestor with compressed air once a year.

Dispose of soot according to environmental protection regulations.

10 Maintenance

10.15 Maintenance for Optional Items

178

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M82 SIGMA CONTROL SMART

No.: 901783 08 USE

Option oe

Option oe