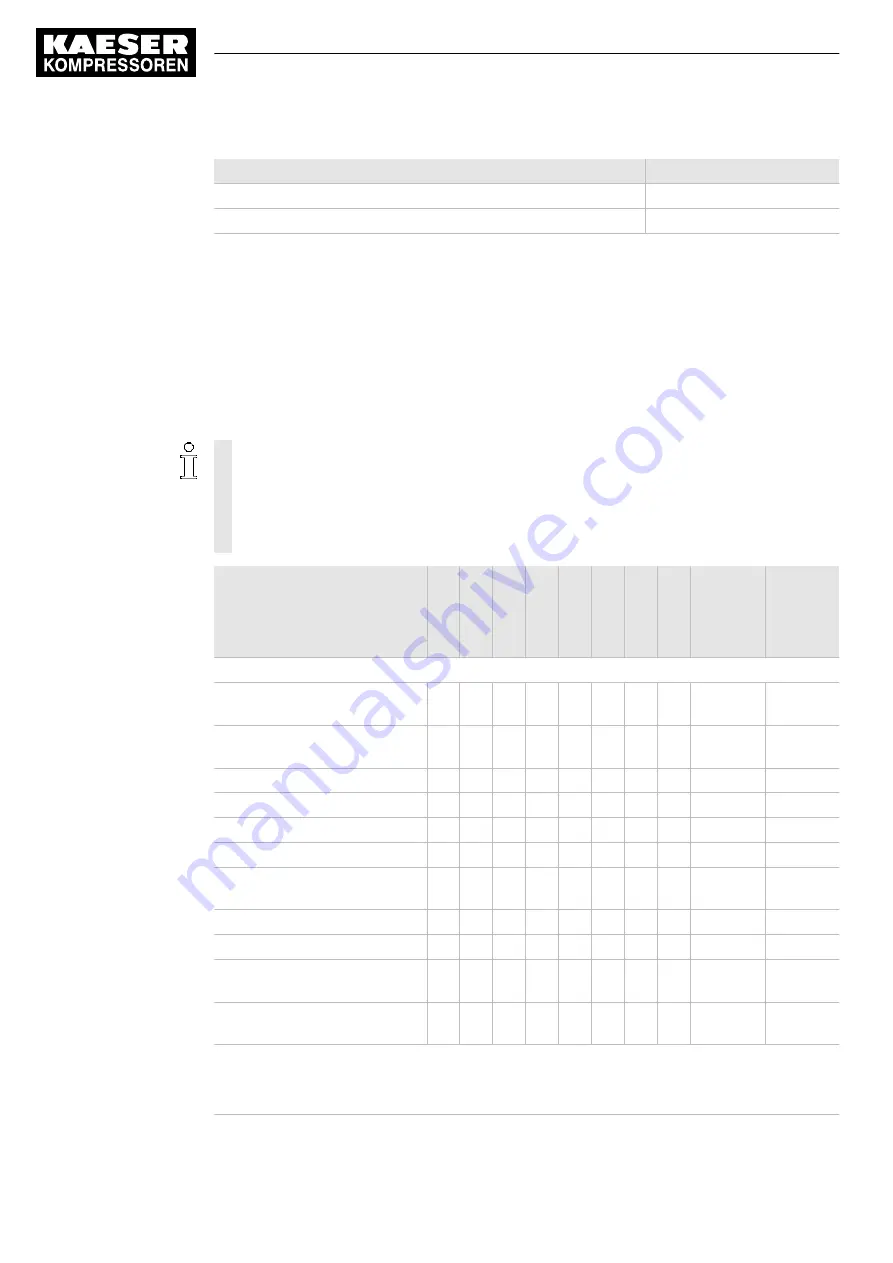

Maintenance interval

Short description

Every 3000 h, at least every 3 years.

A3000

Every 36000 h, at least every 6 years.

A36000

Tab. 94 Maintenance intervals and regular maintenance tasks

The table below lists regular maintenance tasks.

1. Carry out maintenance tasks punctually taking ambient and operating conditions into consider‐

ation.

2. Change consumables and operating fluids according to each site.

10.3.4.1 Machine maintenance schedule

➤ Carry out maintenance tasks on time in accordance with the following schedule:

(*) Observe national regulations.

In Germany: Adhere to the maintenance interval for “Compressor oil change” as per DGUV

Regulation 100 - 500, Chapter 2.11. Oil change as required but at least once a year.

(**) Observe national regulations.

In Germany: As per DGUV Regulation 113-020, it is recommended to change the pressure

hoses for the compressor after 6 years.

Assembly:

Task

Daily

A250

A500

A1000

A1500

A2000

A3000

A36000

See Chapter

Note

Engine:

Clean dust evacuator valve on

engine air filter.

X

Check engine air filter mainte‐

nance indicator.

X

Check engine oil level.

X

Clean engine air filter.

X

Replace the engine oil.

X

Replace the engine oil filter.

X

KS; SW

Check/adjust the drive belt ten‐

sion.

X

KS; SW

Replace the drive belt.

X

KS; SW

Replace engine air filter.

X

Check the intake air line be‐

tween the air filter and engine.

X

KS; SW

Arrange for valves to be adjus‐

ted.

X

KS; SW

KUBOTA = is serviced by a representative from the engine manufacturer (Kubota Corporation)

KS = Contact KAESER SERVICE; SW = Contact specialised workshop

DPF = diesel particulate filter

10 Maintenance

10.3 Maintenance schedules

114

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M82 SIGMA CONTROL SMART

No.: 901783 08 USE