Material Cleaning cloth

Silicone or Vaseline

Precondition The machine is shut down.

The machine is fully vented, the pressure gauge reads 0 psig.

Machine is cooled down.

All compressed air consumers are disconnected and the air outlet valves are open.

1. Open all the doors.

2. Clean the rubber sealing strips with a lint-free cloth and check for cracks, holes and other dam‐

age.

Have any damaged gasket replaced.

3. Properly grease the rubber strips.

4. Close the doors.

10.12 Performing maintenance tasks on the chassis

Perform maintenance tasks on the chassis:

➤ See the separate document "Chassis Operating Manual" for instructions regarding mainte‐

nance tasks on the chassis.

Performing maintenance tasks on the chassis:

➤ Carry out maintenance tasks according to maintenance schedule 10.3.4.1 "Machine's Mainte‐

nance Schedule".

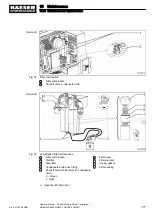

10.13 Check/replace hose lines

Overview of hose lines of machine:

■ Fuel lines of the drive engine

■ Pressure hoses of the drive engine

■ Pressure hoses of the compressor

The hose line are subject to natural aging regardless of proper storage or permitted utilization

during machine operation. This aging changes the material and compound properties and re‐

duces the performance capability of the hose lines. As a result the period of use for hose

lines is limited.

The operator must ensure that all hose lines are checked at reasonable intervals and are re‐

placed if required, see maintenance schedule 10.3.4.1

➤ Comply with all instructions!

10.13.1 Replace the fuel lines of the drive engine

➤ Have an authorized KAESER service representative replace the fuel lines of the drive engine.

10 Maintenance

10.12 Performing maintenance tasks on the chassis

164

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M82 SIGMA CONTROL SMART

No.: 901783 08 USE