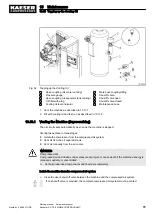

Fig. 28 Air filter maintenance

1

Snap fastener

2

Air filter element

3

Air filter housing

1. Release the spring clips and remove the element.

2. Clean all parts and sealing surfaces.

3. Insert the new element in the housing.

4. Clip the air filter housing onto the inlet valve.

10.7 Drive Motor Maintenance

The drive motor bearings are permanently greased. Subsequent greasing is not necessary.

➤ Have the motor bearings checked by an authorized KAESER Service representative during serv‐

icing.

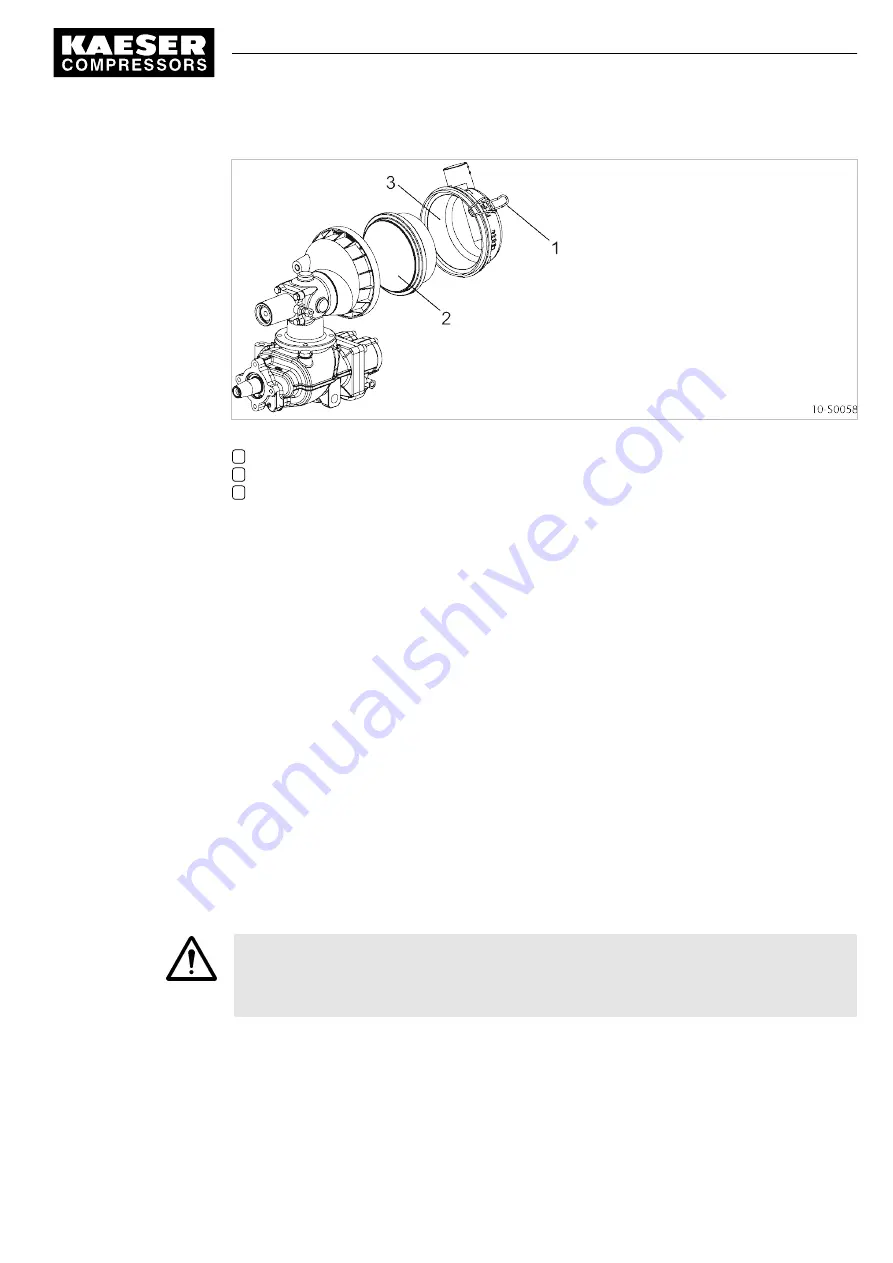

10.8 Maintaining the drive belts

Material Spare parts (if required)

Precondition The supply disconnecting device is switched off,

the device is locked off,

a check has been made that no voltage is present.

The machine has cooled down.

WARNING

Touching moving drive belt may result in severe bruising or even loss of limb or extremities.

➤ Switch off and lock out the power supply disconnecting (isolating) device and check that no

voltage is present.

Make a visual check for damage.

1. Turn the pulley by hand so that all of the belt can be inspected for damage.

2. Change the belts immediately if any damage is found.

10 Maintenance

10.7 Drive Motor Maintenance

Number: 9_6945 01USE

Service manual Screw compressor

Aircenter SX 3/7.5 SIGMA CONTROL BASIC

59