6.2 Reporting Transport Damage

1. Check the machine for visible and hidden transport damage.

2. Inform the carrier and the manufacturer in writing of any damage without delay.

6.3 Connecting the machine with the compressed air network

Condensate in the compressed air network can damage the pipework:

➤ Install only corrosion-resistant pipes.

➤ Use fluoroelastomers as sealing material for seals.

➤ Note the electro-chemical voltage sequence.

➤ Consult with KAESER for suitable materials for the compressed air network.

Precondition The compressed air system is vented completely to atmospheric pressure.

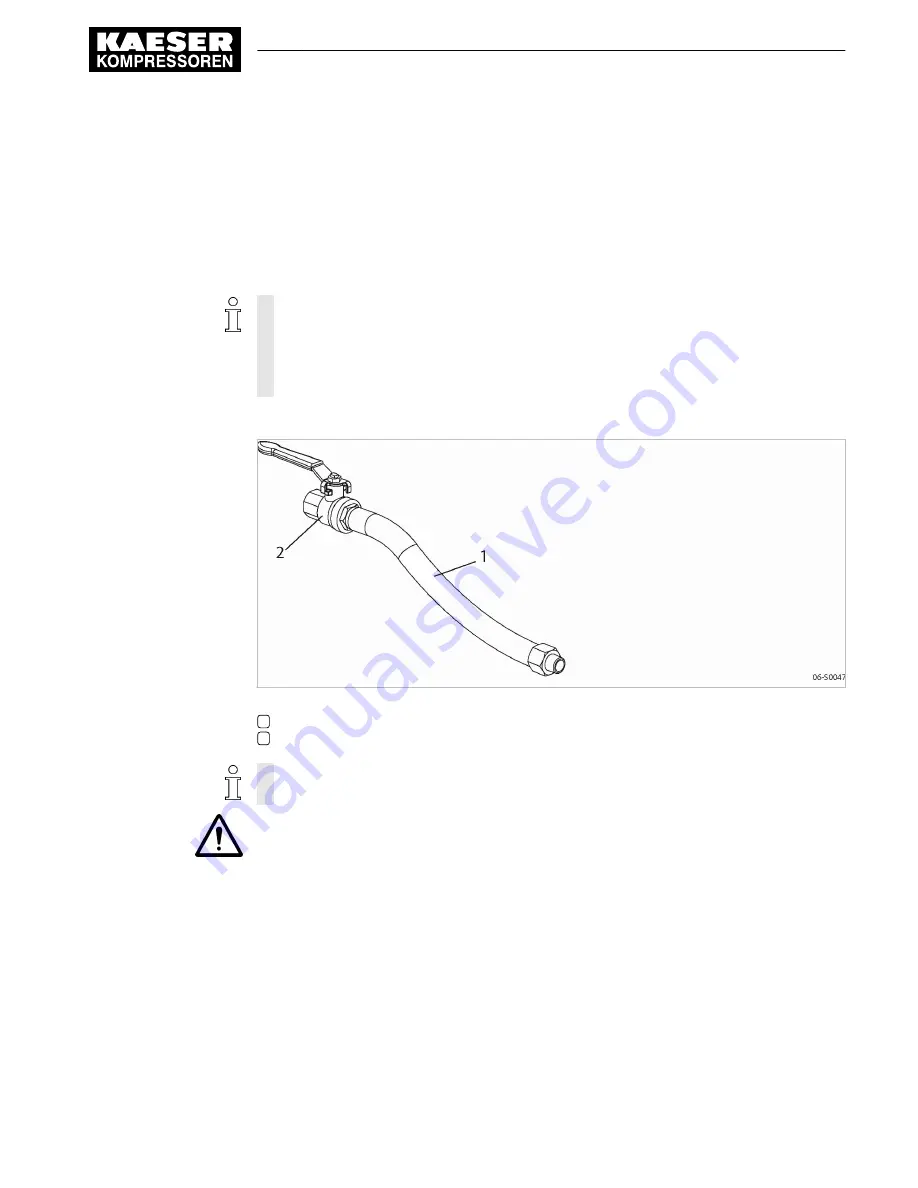

Fig. 10 Compressed pipework

1

Flexible pressure hose

2

Shut-off valve

➤ Do not induce any forces into the machine for which the compressive forces must be bal‐

anced by bracing.

1. WARNING!

Serious injury or death can result from loosening or opening components under pressure.

➤ De-pressurise all pressurised components and enclosures.

2. A shut-off valve must be installed by the user in the connection line.

3. Connect a flexible pressure hose.

Further information The dimensional drawing in chapter 13.3 provides the size and position of the connection ports.

6.4 Connecting the power supply

Precondition The supply isolating device is switched off,

the device is locked off,

the absence of any voltage has been verified.

6

Installation

6.2

Reporting Transport Damage

9_5717 20 E

Service Manual Screw Compressor

ASK T SIGMA CONTROL BASIC

41