7.2 Instructions to be observed before commissioning or re-commis‐

sioning

Incorrect or improper commissioning can cause injury to persons and damage to the machine.

➤ Commissioning may only be carried out by authorised installation and service personnel who

have been trained on this machine.

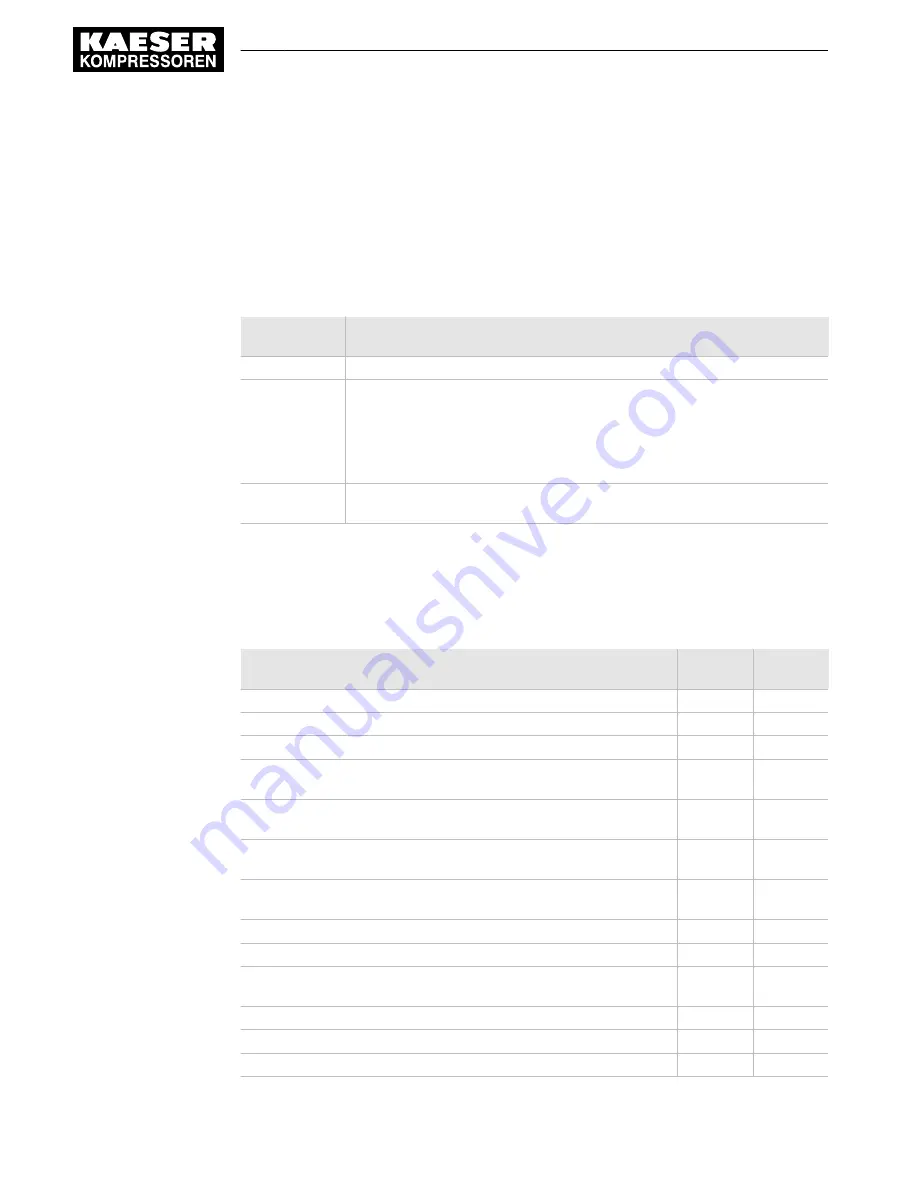

Special measures for re-commissioning after storage

Storage period

longer than:

Remedy

3 months

➤ Manually fill the airend with cooling oil.

12 months

➤ Change the oil filter.

➤ Change the oil separator cartridge.

➤ Change the cooling oil.

➤ Have the motor bearings checked by an authorised KAESER Service Tech‐

nician.

36 months

➤ Have the overall technical condition checked by an authorised

KAESER Service Technician.

Tab. 45 Re-commissioning after storage

7.3 Checking installation and operating conditions

➤ Check and confirm all the items in the checklist before starting the machine.

To be checked

See

chapter

Confirmed?

➤ Are the operators fully conversant with safety regulations?

–

➤ Have all the positioning conditions been fulfilled?

5

➤ Is a user's lockable power supply disconnecting device installed?

6.4

➤ Does the power supply conform to the specifications on the name‐

plate?

2.1

➤ Are the power supply cable conductor cross-sections and fuse rat‐

ings adequate?

2.14

➤ Drive motor overload protection switch set according to the mains

voltage?

7.4

➤ Option T2: Do the connections to the transformer correspond with

the mains supply?

6.4.1

➤ Have all electrical connections been checked for tightness?

–

➤ Is a shut-off valve fitted to compressed air outlet?

6.3

➤ Has the connection to the air system been made with a hose or axial

compensator?

6.3

➤ Is the condensate drain connected?

6.5

➤ Has the drive belt tension been checked?

10.9

➤ Is there sufficient cooling oil in the separator tank?

10.12

7

Initial Start-up

7.2

Instructions to be observed before commissioning or re-commissioning

46

Service Manual Screw Compressor

ASK T SIGMA CONTROL BASIC

9_5717 20 E