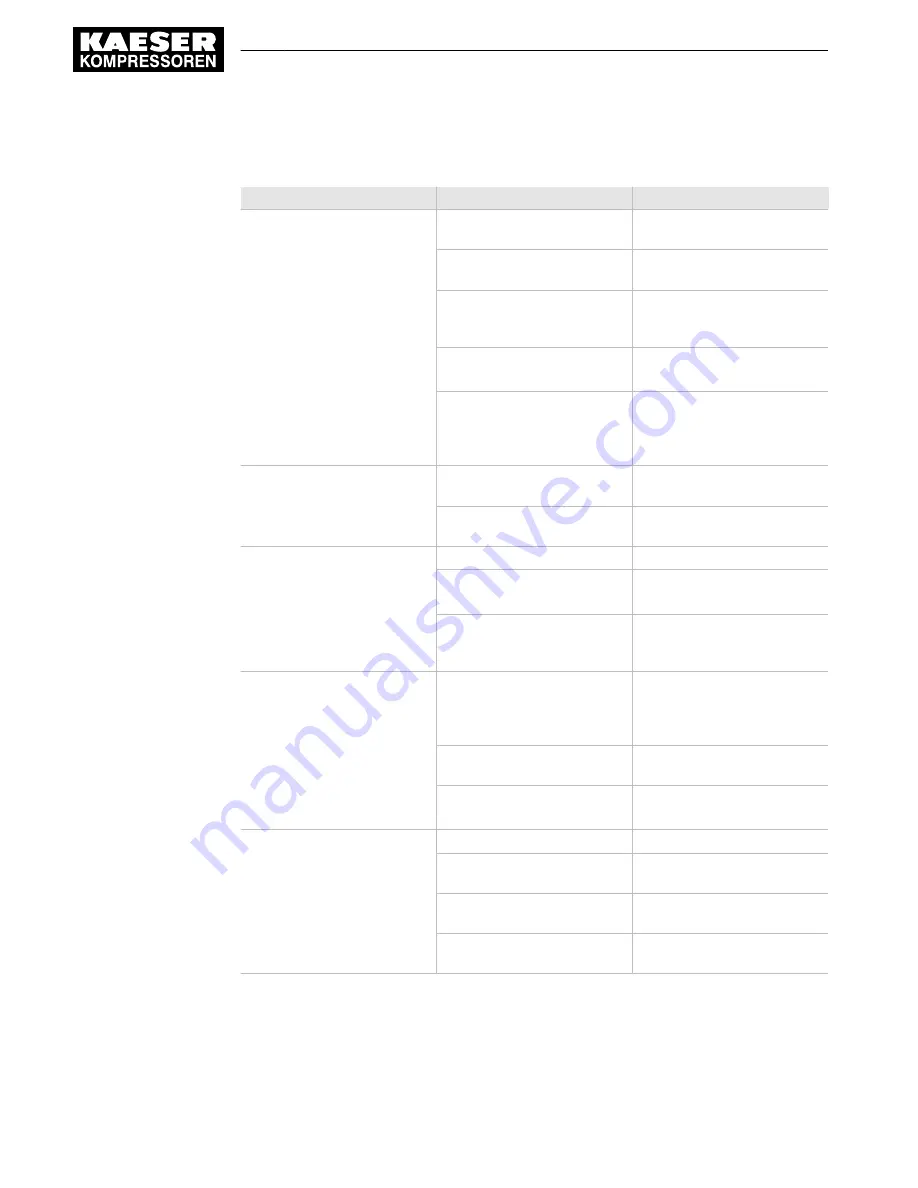

9.4 Other Faults

Fault

Possible cause

Remedy

Machine runs but produces no

compressed air.

Inlet valve not opening or only

opening partially.

Call KAESER service represen‐

tative.

Venting valve not closing.

Call KAESER service represen‐

tative.

Leaks in the pressure system.

Check pipework and connec‐

tions for leaks and tighten any

loose fittings.

Air consumption is greater than

the capacity of the compressor.

Check the air system for leaks.

Shut down the consumer(s).

Hose coupling or maintenance

hose still plugged into the

quick-release coupling on the

oil separator tank.

Remove coupling or mainte‐

nance hose.

Cooling oil runs out of the air fil‐

ter.

Oil level in the oil separator

tank too high.

Drain off oil until the correct lev‐

el is reached.

Inlet valve defective.

Call KAESER service represen‐

tative.

Compressor switches between

LOAD and IDLE more than

twice per minute.

Air receiver too small.

Increase size of air receiver.

Airflow into the compressed air

network restricted.

Increase air pipe diameters.

Check filter elements.

The differential between cut-in

and cut-out pressure too is

small.

Check switching differential.

Cooling oil leaking into the floor

pan.

Hose coupling or maintenance

hose still plugged into the

quick-release coupling on the

oil separator tank.

Remove coupling or mainte‐

nance hose.

Oil cooler leaking.

Call KAESER service represen‐

tative.

Leaking joints.

Tighten joints.

Replace seals.

Cooling oil consumption too

high.

Unsuitable oil is being used.

Use SIGMA FLUID cooling oil.

Oil separator cartridge split.

Change the oil separator car‐

tridge.

Oil level in the oil separator

tank too high.

Drain off oil until the correct lev‐

el is reached.

Oil return line clogged.

Check dirt trap in the return

line.

Tab. 51 Other faults and actions

9

Fault Recognition and Rectification

9.4

Other Faults

58

Service Manual Screw Compressor

ASK T SIGMA CONTROL BASIC

9_5717 20 E