Di

e Ze

ic

hnun

g b

le

ib

t un

ser au

ssch

lie

ßli

ch

es

E

ig

en

tu

m

. S

ie

wird n

ur

zu d

em

v

erein

barte

n Zw

ec

k

an

vertraut

un

d d

arf z

u

kei

ne

m

andere

n

Zwec

k

ve

rwend

et w

erde

n.

Ko

pien

od

er s

on

st

ige

Ver

vie

lfäl

tigung

en

ei

ns

chl

ieß

lic

h Sp

ei

cheru

ng,

Verarbe

itun

g o

der Ver

breit

un

g u

nter

Verw

en

dung

el

ektr

on

is

cher S

ys

te

me d

ürfen

nur

zu d

em v

ere

in

barte

n Zwe

ck

an

gef

erti

gt w

erden.

W

ed

er Origin

al

no

ch Ver

vi

el

fäl

tigu

ng

en

dürfe

n Dritt

en

au

sgehä

nd

ig

t oder

in

s

onst

ig

er W

ei

se z

ug

ängl

ic

h g

em

ac

ht w

erde

n.

Drawin

gs r

em

ai

n o

ur ex

cl

us

iv

e pro

perty.

The

y

are e

ntrust

ed

on

ly

for th

e a

gree

d p

urpo

se. C

op

ie

s

or an

y

other

reprod

uct

io

n, in

cl

ud

ing

storag

e, tre

at

me

nt an

d d

is

se

m

inat

io

n b

y

us

e o

f ele

ctr

oni

c

syst

em

s

mu

st

not b

e

made

for a

ny

other th

an

the

agre

ed

purp

os

e. N

ei

ther ori

gi

na

ls

nor re

prod

uct

io

ns

m

ay

be gi

ven

to

or mad

e a

vai

labl

e t

o t

hird p

arti

es.

En

twi

ck

lu

ng

sbe

di

ngt

e

Än

deru

ngen

vo

rbe

halt

en.

Zei

chn

un

g d

arf nur üb

er

CA

D geä

nd

ert w

erden.

Status

Dokument TZD

Bezeichnung

Freigeg.

Bearb.

Gez.

Original

Blatt

Sprache

Name

Datum

Maßstab

Projektion

Änderungs-Nr.

USE

F R E I G E G E B E N

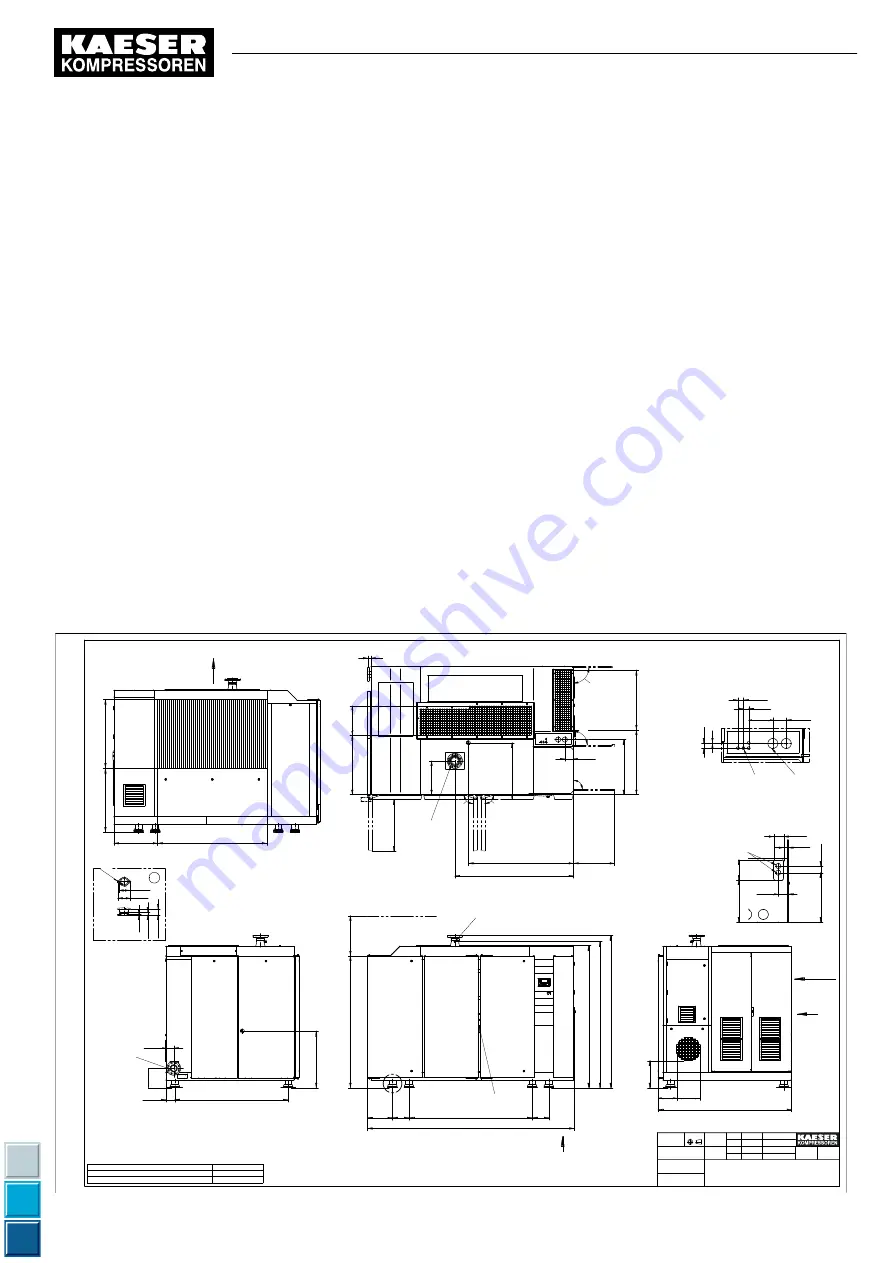

Dimension and connection dim.

DRESSEL4

MALTER1

MALTER1

03.09.2013

30.08.2013

ESD.2C SFC K1

23.05.2013

1 von 1

Dokument TZM

10248151 USE 00

A2

Stan

d 12.11.20

12

10248151 D 00

4 x dia.26

2 x dia.75

Gas discharge

ANSI 3" / 300lbs

ATTENTION!

Minimum width of door is total width of unit + 100 mm

CG : Centre of gravity

position marginally dependent on design

CG

Electrical connections

as required

3 7/8

7 1/8

1 5/8

40

2 x dia.75

29

1/8

3

7/8

5 3/4

2 1/2

5 7/8

11 3/

4

24

7/

8

B

Electrical connections as required

Z

1 5/8

Y

Option:

Code:

Machine mountings

H 1

Air cooling

K 1

8 3/8

7 1/8

O

1/2

H1

Z

Relubrication equipment

for motor bearings

Demounting height for separating cartridge

Oil return line

Swagelok SS 400-1-2

Cooling air inlet

A

33

1/

2

30 5/

8

CG

17

1/

4

38 1/

4

35

3/

8

62 1/4

24 1/4

32

1/

2

5 1/8

2

90°

90

°

90°

90

°

90°

Gas inlet

ANSI 4" / 150lbs

35

1/

4

25 7/8

37 3/

4

40

1/

2

Cooling air outlet

A

64 5/8

B

14 3/4 9 7/8

72 7/8

9 7/8

122

78

23

5/8

84

1/

8

16

11

13 3/4

79

4 5/8

1/8

1 7/

8

3

7/

8

70 1/8 ±0,4

19

7

/8

±0

,4

90

1/

8

86

3/

8

5

Y

5 1/4

67

11

3/

8

CG

33

1/

2

13 Annex

13.2 Dimensional drawing

ESD_2C_10357405_10–LIN_00 E

Service Manual Screw Compressor

ESD 442/14 bar (abs) SFC SIGMA CONTROL 2

89

Summary of Contents for ESD 352 SFC

Page 5: ......

Page 6: ......

Page 7: ......

Page 8: ......

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 15: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 171: ...KKW SSC 2 03 en 01 BA SIGMA CONTROL FLUID KKW SSC 2 03 01 20130805 113302...

Page 173: ......

Page 175: ...Contents ii Quick user guide Controller SIGMA CONTROL 2 SCREW FLUID 1 1 3 9_9450 03 USE...

Page 215: ...Contents iv Service manual Controller SIGMA CONTROL 2 SCREW FLUID 1 1 3 9_9450 03USE...

Page 392: ...KKW GBASE 1 00 en ERSATZTEILE 10357405_10 ESD 2C 20130903 115349...