6.7.2 Option K2/K9

Connecting the cooling water

➤ Take the electrochemical series into consideration and choose suitable materials for wa‐

ter connections.

➤ Keep the effect of pressure surges on the coolers as low as possible.

➤ Install an expansion tank to act as a pulsation damper if pressure surges cannot be avoi‐

ded.

➤ Avoid a low inlet temperature for the cooling water as it can cause condensation. If re‐

quired, contactKAESER for suitable insulation measures.

Temperature-controlled cooling water supply systems, to which numerous machines are connec‐

ted, regulate the water flow rate according to the difference in temperature between the supply and

the return water. Individual machines may not receive an adequate flow under this system. Break‐

downs are the result.

➤ KAESER can advise on how to ensure the cooling water supply via suitable control

valves.

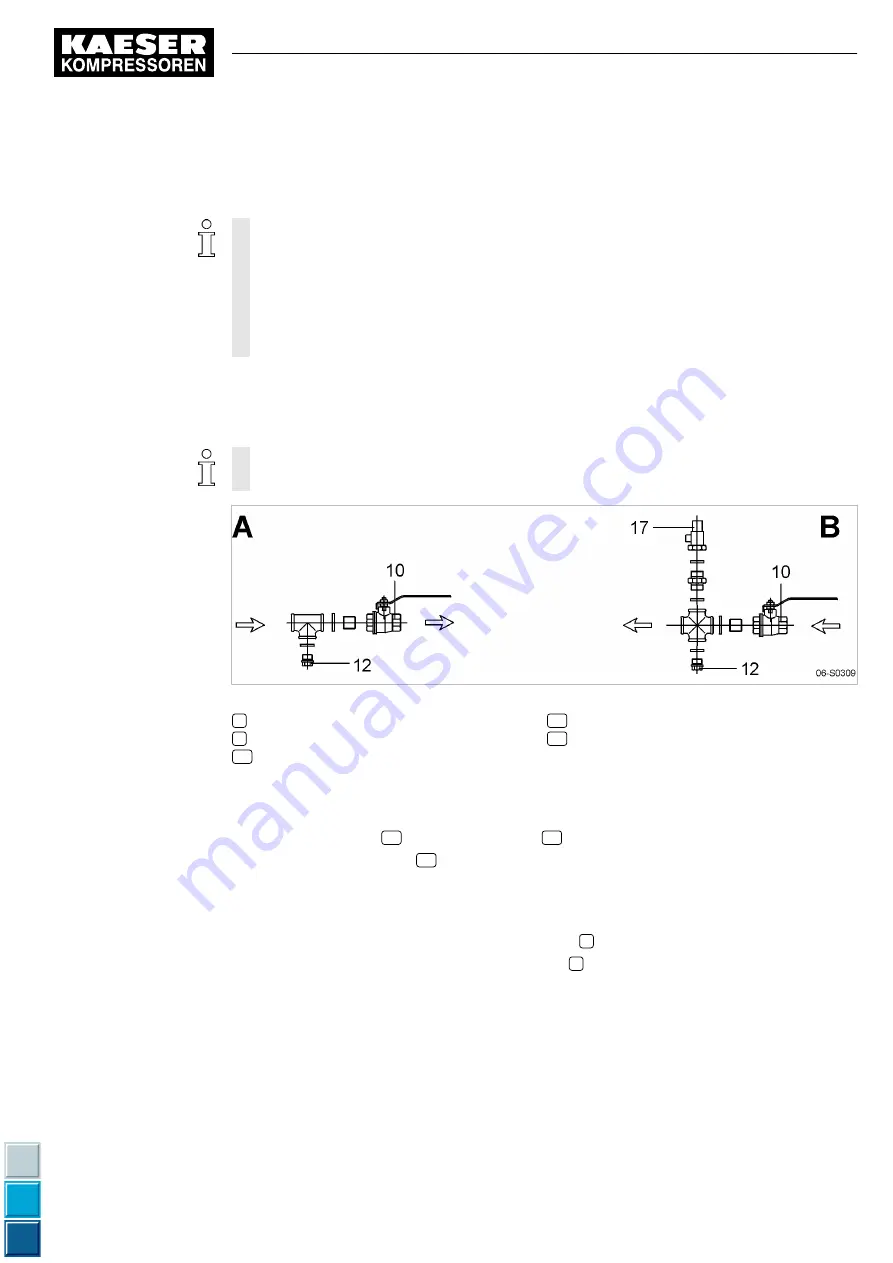

Fig. 13 Connecting the cooling water

A

Cooling water outlet

B

Cooling water inlet

10

Shut-off valve

12

Connection port with plug

17

Pressure relief valve

1. The user is to provide the following fittings:

■ Dirt traps (grid size according to permissible particle size.

■ Shut-off valves

10

and connection ports

12

for maintenance and venting

■ Pressure relief valve

17

to prevent build-up of excessive pressure.

Activating pressure and blow-off capacity of the safety valve are governed by the user's in‐

stallation design. The technical specification of the cooler must be taken into account.

2. Connect the cooling water lines to the fittings.

3. Open the shut-off valve on the cooling water outlet

A

.

4. Slowly open the cooling water inlet shut-off valve

B

to gradually fill the cooler with water.

5. Bleed air from the water lines.

Further information The dimensional drawing in chapter 13.2 gives the flow direction, size and location of the connec‐

tion ports.

6

Installation

6.7

Options

ESD_2C_10357405_10–LIN_00 E

Service Manual Screw Compressor

ESD 442/14 bar (abs) SFC SIGMA CONTROL 2

41

Summary of Contents for ESD 352 SFC

Page 5: ......

Page 6: ......

Page 7: ......

Page 8: ......

Page 9: ......

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 15: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 171: ...KKW SSC 2 03 en 01 BA SIGMA CONTROL FLUID KKW SSC 2 03 01 20130805 113302...

Page 173: ......

Page 175: ...Contents ii Quick user guide Controller SIGMA CONTROL 2 SCREW FLUID 1 1 3 9_9450 03 USE...

Page 215: ...Contents iv Service manual Controller SIGMA CONTROL 2 SCREW FLUID 1 1 3 9_9450 03USE...

Page 392: ...KKW GBASE 1 00 en ERSATZTEILE 10357405_10 ESD 2C 20130903 115349...