10.4.5 Oil separator tank dirt trap maintenance

Material Cleaning cloth

Wrench

Small screwdriver

Maintenance kit, control valve

Petroleum ether or spirit

Precondition The machine is shut down.

The machine is fully vented, the pressure gauge reads 0 bar.

Machine is cooled down.

All compressed air consumers are disconnected and the air outlet valves are open.

The negative cable to the battery is disconnected.

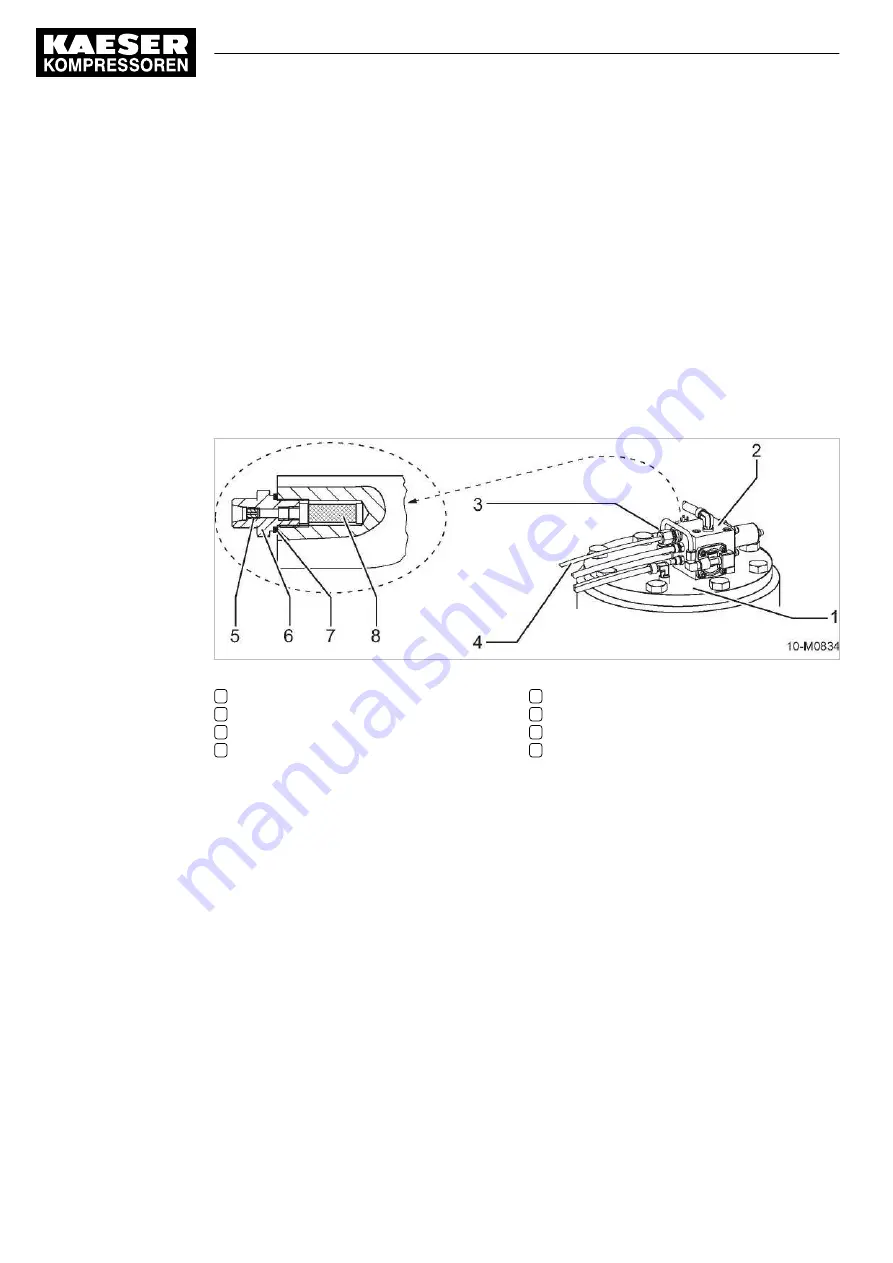

Fig. 56 Oil separator tank dirt trap maintenance

1

Oil separator tank cover

2

Control valve

3

Union nut

4

Oil return line

5

Nozzle

6

Screw-in connector

7

Gasket

8

Strainer

➤ Open the right-hand access door.

Dirt trap maintenance:

1. Undo the union nut and bend the oil return line to one side.

2. Unscrew the screw-in connector.

3. Unscrew the strainer from the screw-in connector.

4. Use a screwdriver to unscrew the nozzle from the screw-in connector.

5. Clean the housing, strainer and sealing ring with cleaning solvent or spirit.

6. Check the nozzle, strainer and sealing ring for wear.

Replace components if they are heavily worn.

7. Fit the nozzle and strainer to the screw-in connector.

8. Screw in the connector making sure the sealing ring seats properly.

9. Refit the oil scavenge line.

10 Maintenance

10.4 Compressor Maintenance

128

Operator manual Portable compressor

M 64

No.: 9_5898 26 E

RAMIRENT