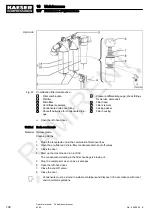

Fig. 63 Cleaning the compressed air aftercooler

1

Compressed air after-cooler

2

Direction of impacting water or steam jet (from inside to outside).

1. Seal off the air intakes of the engine and compressor air filters before starting cleaning.

2. Clean the aftercooler with compressed air, water or steam jet in the opposite direction to the

cooling air flow (from inside to outside).

3. Remove the protective coverings from the air filter intake openings.

4. Reconnect the battery.

5. Close the doors.

6. Start the machine and run up to operating temperature so that excess water is evaporated.

Clean the cooler blades only in a washing area equipped with an oil separator.

10.6 Maintenance of rubber sealing strips

The rubber sealing strips between the body panels and the access doors serve both as a sound‐

proofing measure and to prevent ingress of rain water.

Care of the rubber sealing strips is especially necessary in winter to prevent the strips from sticking

and tearing when the access panels are opened.

Material Cleaning cloth

Silicone or Vaseline

Precondition The machine is shut down.

The machine is fully vented, the pressure gauge reads 0 bar.

Machine is cooled down.

All compressed air consumers are disconnected and the air outlet valves are open.

1. Open all the doors.

2. Clean the rubber sealing strips with a lint-free cloth and check for cracks, holes and other dam‐

age.

Have any damaged gasket replaced.

3. Properly grease the rubber strips.

4. Close the doors.

10 Maintenance

10.6 Maintenance of rubber sealing strips

No.: 9_5898 26 E

Operator manual Portable compressor

M 64

139

Option da, db, dc, dd

RAMIRENT