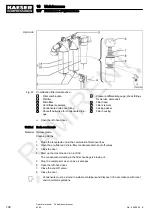

2. Turn the nut

12

by hand until there is no gap between the sleeve

11

and spherical seat wash‐

er

10

and/or washer

20

.

3. Lock the nut

19

with the nut

12

.

4. Tighten the nut

8

against the side of the tensioning frame

4

. The conical seat washer

9

and

the spherical seat washer

23

must lay in the tensioning frame.

5. Lock the nut

24

with the nut

8

.

Making operational:

1. Re-attach the safety screen and the belt guard.

2. Reconnect the negative battery terminal.

3. Close the door.

10.7.8.4 Changing the belt

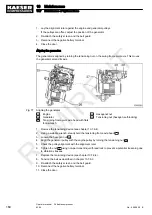

1. Remove the tensioning device (see Fig. 75).

■ Loosen nuts

24

and

8

and lock together at the end of the threaded rod

7

.

■ Loosen nuts

19

and

12

on the tensioning frame

4

until the belt is completely slack.

■ Loosen the locking nut

18

.

■ With the help of the nut

6

, unscrew the tensioning device

8

from the locknut

15

.

■ Remove the tensioning device

6

from the tensioning frame

4

and belt tensioner holder

5

.

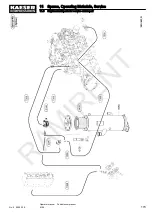

2. Changing the belts

■ Remove the belts from the pulleys.

■ Check the pulleys for dirt and wear.

─ Clean the pulleys.

─ Slitt remskive: Skift ut remskiven.

■ Check that the pulleys are lined up.

─ If the pulleys are not lined up, adjust the position of the generator until they are.

■ Without using force, place the new belt over the engine and generator pulleys.

3. Mount the tensioning device (see Fig. 75).

■ Mount the tension device

6

in in the tensioner holder

5

and tensioning frame

4

as illus‐

trated.

■ Lock the nut

8

to the nut

24

.

■ Tighten the tensioning device

6

to the side of the motor with the nut

15

. For this, the ten‐

sioning device must be screwed into the locknut

15

.

■ Use a wrench to fixate the nut

18

. Use another wrench to turn nut

8

counter-clockwise.

Secure the nut

18

with a drop of liquid thread lock to prevent a potential loosening due to

vibration stresses.

■ Tension the belt as described in chapter 10.7.8.3.

A belt that has been replaced may not be used again.

Old belts should be disposed of in accordance with the latest environmental regulations.

Making operational:

1. Re-attach the safety screen and the belt guard.

10 Maintenance

10.7 Maintenance of Optional Items

158

Operator manual Portable compressor

M 64

No.: 9_5898 26 E

RAMIRENT