When the filter medium has trapped a specific amount of soot, it is regenerated while the machine

is under LOAD. The control unit initiates and monitors the regeneration process. Diesel fuel is in‐

jected into the exhaust stream. This causes a special catalyst to heat the exhaust gas to over

550 °C and the soot is burnt off the filter medium in CO₂.

The machine is shut down if the back pressure in the exhaust exceeds a specific value.

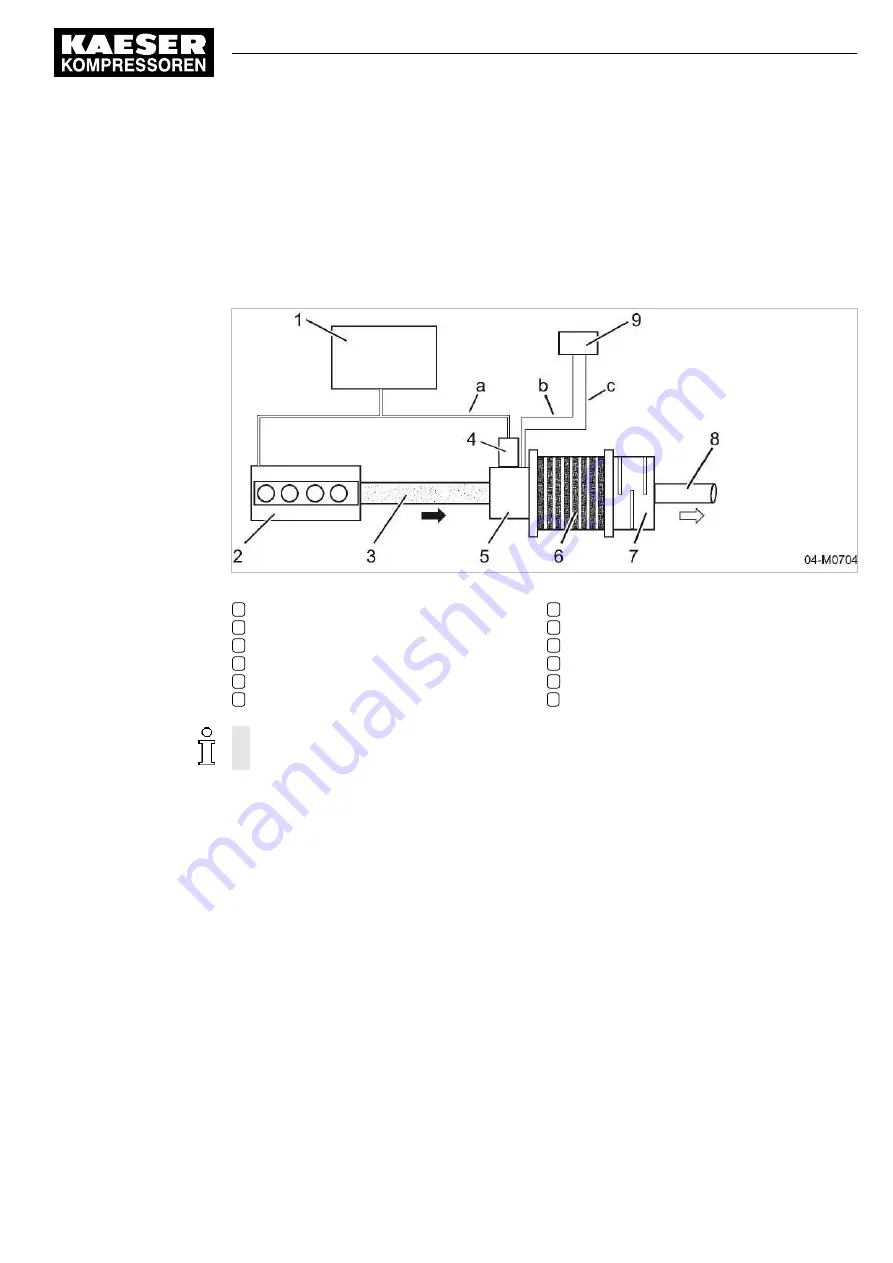

General design

Fig. 17 General design of the diesel particulate filter system

1

Fuel tank

2

Diesel engine

3

Exhaust pipe with contaminated gases.

4

Diesel injection

5

Oxidizing catalytic converter

6

Filter module

7

Silencer module

8

Outlet of cleaned exhaust gas

9

Electronic control unit

a

Fuel line

b

Exhaust back pressure monitor

c

Exhaust gas temperature monitor

The diesel particulate filter system meets the requirements of TRGS 554, TA and VERT

(Switzerland).

4.6.7 Option ua

Hose reel option

The machine is provided with an extension hose to allow connection and operation of remote air

tools. A hose reel is provided for safe storage of this hose.

4.6.8 Option sf

Optional anti-theft device

The machine is fitted with a security chain as theft protection.

4.6.9 Option sg

Pedestrian protection option

The machine is provided with pedestrian protection that functions both as a deflector and against

pedestrians being run-over.

4

Design and Function

4.6

Options

No.: 9_5898 26 E

Operator manual Portable compressor

M 64

55

RAMIRENT