10.4.3 Fuel system maintenance

Material Spare parts

Receptacle

Cleaning cloths

Precondition The machine is shut down.

The machine is standing level.

The machine is fully vented, the pressure gauge reads 0 bar.

Machine cooled down.

All compressed air consumers are disconnected and the air outlet valves are open.

The «battery isolating switch» is off.

DANGER

Danger of fire from spontaneous ignition of fuel!

Serious injury or death could result from the ignition and combustion of fuel.

➤ Allow no open flames or sparks at the place of use.

➤ Stop the engine.

➤ Wipe up escaped fuel.

➤ Keep fuel away from hot machine parts.

➤ Ensure that the maximum ambient temperature is not exceeded at the place of use.

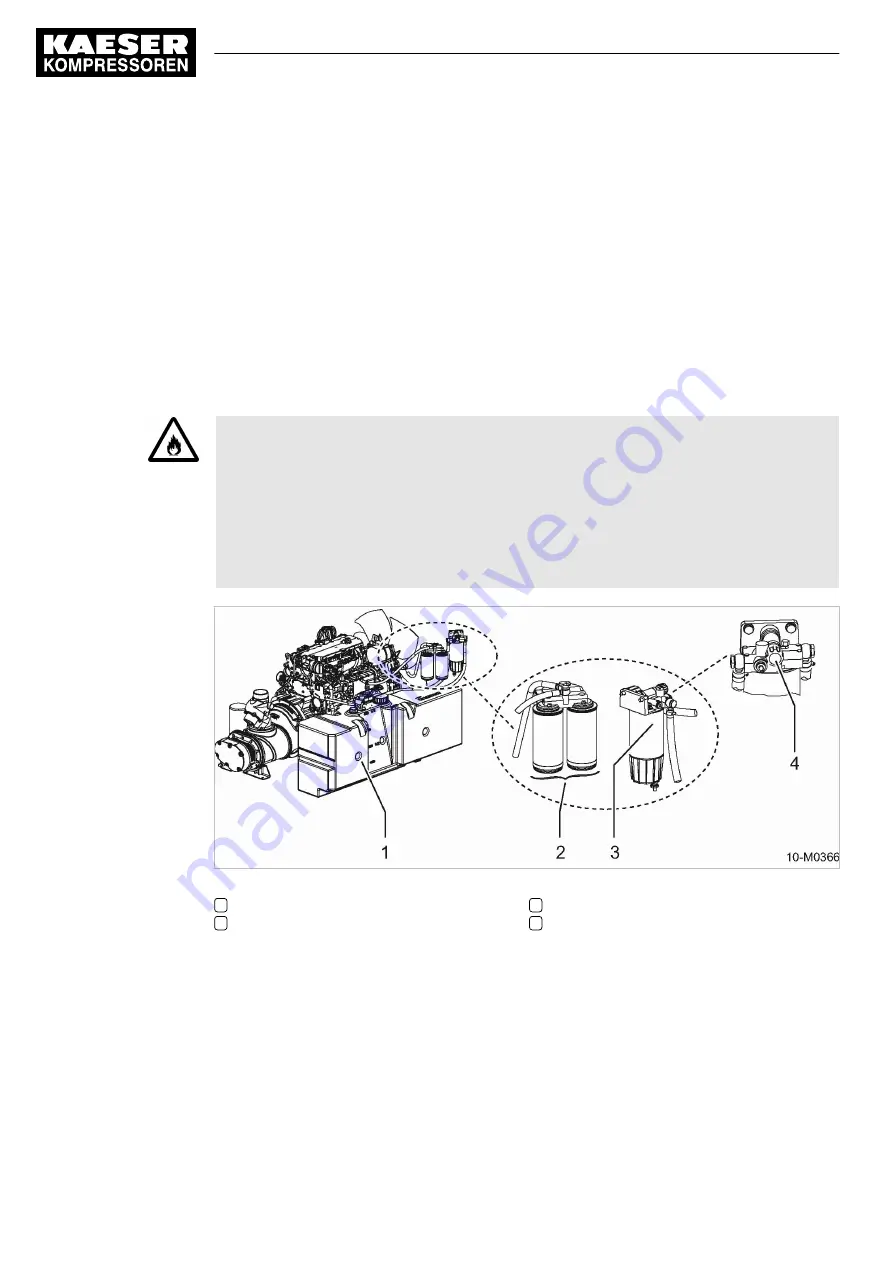

Fig. 52 Fuel system maintenance

1

Fuel tank

2

Fuel fine filter

3

Fuel prefilter with water trap

4

Manual fuel pump with bayonet fitting

10.4.3.1 Bleeding the fuel system

Air can enter the fuel system if the fuel tank is empty, after a fuel filter change or when carrying out

work on the fuel lines.

Bleed the fuel system if the engine refuses to start despite the fact that the fuel tank is full.

1. Open the right-hand access door.

2. Unlatch the manual fuel pump bayonet lock by pressing and turning anti-clockwise.

The pump piston is pushed out by the spring.

3. Pump the piston until high resistance is felt.

10 Maintenance

10.4 Engine

110

Service Manual Screw Compressor

M135 SIGMA CONTROL MOBIL

No.: 9_6975 00 E