10.7 Rubber sealing strip maintenance

The rubber sealing strips between the body panels the access doors serve both as a soundproofing

measure and to prevent ingress of rain water.

Care of the rubber sealing strips is especially necessary during the winter months to prevent the strips

from sticking and tearing when the access panels are opened.

➤ Lubricate the rubber sealing strips regularly with silicone oil or Vaseline.

10.8 Chassis

➤ Carry out maintenance according to the schedule in chapter 10.3.3.1.

10.8.1 Wheel checks

Check the wheels and tyres after the first 50 km and after every wheel change, but at least every six

months for tightness, visible damage and tyre pressures.

Material Torque wrench

Tyre pressure gauge

Precondition The machine is switched off.

1. Check that the wheel fixings are tight.

2. Check the tyres for any defect.

Replace any damaged or worn tyres.

3. Check the tyre pressures.

Further information See chapter 2.4.3 for wheel fixing torques.

See chapter 2.4.2 for tyre pressures.

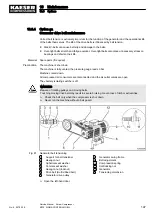

10.8.2 Towbar maintenance

Clean and lubricate all sliding and rotating bearings as necessary but at least every 6 months.

Material Lithium enriched multi-purpose grease

Acid-free oil

Cleaning cloths

Precondition The machine is shut down.

The machine is disconnected from the towing vehicle and safely parked.

10 Maintenance

10.7 Rubber sealing strip maintenance

136

Service Manual Screw Compressor

M135 SIGMA CONTROL MOBIL

No.: 9_6975 00 E