10.6 Maintain rubber sealing strips

The rubber sealing strips between the lower body and the canopy serve both as a soundproofing

measure and to prevent ingress of rain water.

Care of the rubber sealing strips is very necessary during the winter months to prevent the strips

from sticking and tearing when the canopy is opened.

➤ Lubricate the rubber sealing strips regularly with silicone oil or Vaseline.

10.7 Options

➤ Carry out maintenance tasks in accordance with the schedules in chapter 10.2.3.2 .

10.7.1 Option ea

Tool lubricator maintenance

Material Tool oil (special lubricant for road breakers),

Funnel

Cleaning cloths

Precondition The machine is shut down.

The machine is fully vented, the pressure gauge reads 0 bar.

Machine cooled down.

All compressed air consumers are disconnected and the air outlet valves are open.

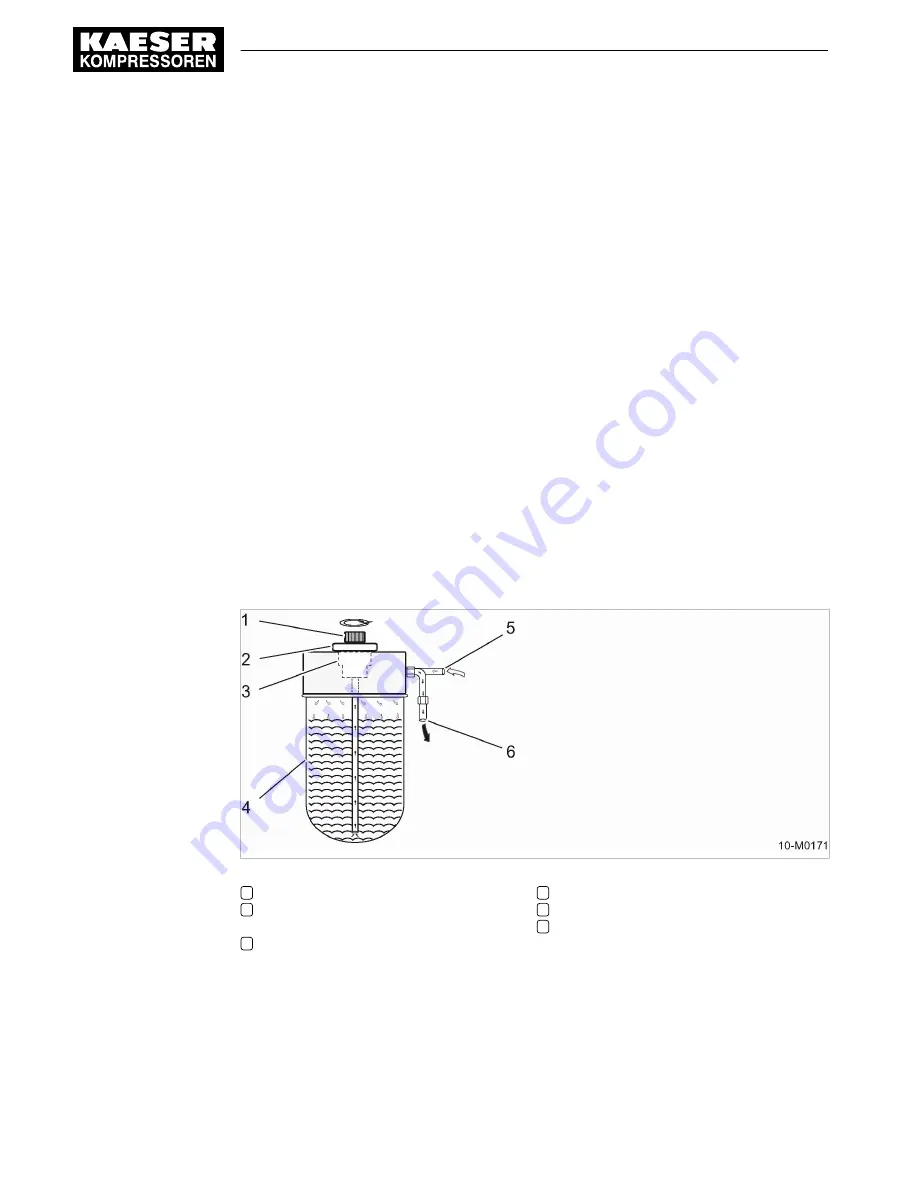

Fig. 41 Tool lubricator maintenance

1

Metering knob

2

Filler plug with dipstick and integrated riser

tube

3

Oil filler port

4

Oil tank

5

Compressed air inlet

6

Tool oil outlet

Checking the tool lubricator oil level

Check the oil level daily.

1. Raise the canopy.

10 Maintenance

10.6 Maintain rubber sealing strips

102

Service Manual Screw Compressor

M43

No.: 9_9432 02 E

RAMIRENT