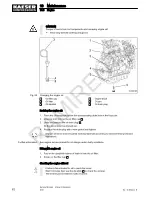

7. Insert the new element.

8. Replace the filter cap.

9. Connect the fuel line.

10. Tighten the hose clamp.

11. Bleed the system as described previously.

Catch any escaping fuel.

Dispose of escaped fuel, contaminated fuel and working materials and components contami‐

nated with fuel according to environmental regulations.

Replacing the filter cartridge of the main fuel filter:

The filter cartridge of the main fuel filter should be changed according to the maintenance sched‐

ule.

Use a filter wrench to loosen the cartridge if necessary.

Precondition The negative cable to the battery is disconnected!

1. Place a receptacle under the filter cartridge

5

.

2. Unscrew and remove the cartridge

5

.

3. Take a new filter cartridge.

4. Smear fuel on the gasket.

5. Spin on the new oil filter by hand until the gasket is firmly seated.

6. Bleed the system as described previously.

Catch any escaping fuel.

Dispose of escaped fuel, contaminated fuel and working materials and components contami‐

nated with fuel according to environmental regulations.

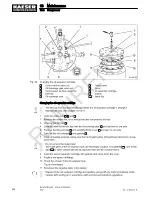

Starting the machine and performing a test run:

1. Start the machine and allow it to idle for about 1 minute.

2. Visually check the fuel system for leaks.

3. Shut down the machine.

4. Tighten all fittings.

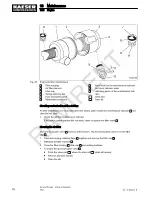

10.3.3.1 Option ne

Maintenance of the fuel prefilter with water trap

A combined water trap and filter element is used to clean the fuel.

Material Spares

Wrench

Receptacle

Cleaning cloths

Precondition The machine is shut down.

The machine is standing level.

The machine is fully vented, the pressure gauge reads 0 bar.

Machine cooled down.

10 Maintenance

10.3 Engine

No.: 9_9432 02 E

Service Manual Screw Compressor

M43

79

RAMIRENT