3. If the machine is to be unused for a number of weeks, remove the battery and store in a frost

proof room.

In extreme cases, the use of heavy-duty cold-start batteries (to DIN 75311) and/or additional

batteries is recommended.

10.3.6.3 Battery removal and installation

Precondition The machine is shut down.

The machine is standing level.

The machine is fully vented, the pressure gauge reads 0 bar.

Machine cooled down.

1. WARNING!

There is danger of batteries bursting.

If a battery is short circuited it will overheat and can burst.

Battery electrolyte will be sprayed out in such an event.

➤ Never short-circuit a battery (e.g. with a hand tool).

➤ Always wear protective gloves.

2. CAUTION!

Excessive voltage produced by the alternator.

Voltage peaks can destroy the alternator regulator and diodes.

➤ The battery serves as a buffer and must not be disconnected while the engine is running.

3. Disconnect the negative cable first, then the positive cable.

4. Unscrew the battery fixing clamp.

5. Replace in the reverse order.

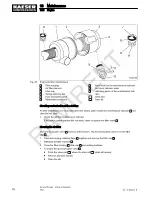

Battery replacement

Replacement batteries must have the same capacity, current strength and form as the original bat‐

teries.

➤ Always replace a battery with one of the same type.

Old batteries are special waste and must be disposed of correctly in accordance with local

environment protection regulations.

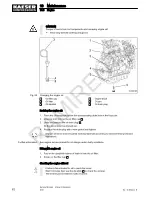

10.4 Compressor

➤ Carry out maintenance according to the schedule in chapter 10.2.3.1.

10.4.1 Checking cooling oil level

The oil level is checked at the oil separator tank filling port. Oil must be visible in the port when the

filler plug is removed.

10 Maintenance

10.4 Compressor

No.: 9_9432 02 E

Service Manual Screw Compressor

M43

87

RAMIRENT