Technical Specification

1 --- 4

S -- SERIES SYNTHETIC LUBRICANTS

-

S---Series SIGMA compressor oils are formulated from the most advanced synthetic

lubricants. These ”synthetic” lubricants begin as high quality petroleum feed stock.

They are then refined, processed and purified into fluids with very consistent molecular

structure. These oils are carefully blended to produce extremely consistant lubricants

with superior properties. SIGMA synthetic lubricants feature all the advantages of both

PAO and diester fluids.

-

S---460 lubricant is recommended for compressors operating in ambient temperatures

between 40

F and 105

F.

Specialty KAESER LUBRICANTS

-

S---680 lubricant may be used when ambient temperatures are always between 70

F

and 105

F.

-

FG---460 synthetic hydrocarbon based food grade fluid is designed for use in rotary

screw compressors in the application where incidental food contact may occur with

the discharge air. This fluid meets the requirements of the FDA Regulation 21 CFR

§178.3570 and is USDA H---1 approved. FG---460 is approved for canning, food pack-

ing, meat and poultry processing and other applications where incidental food contact

may occur.

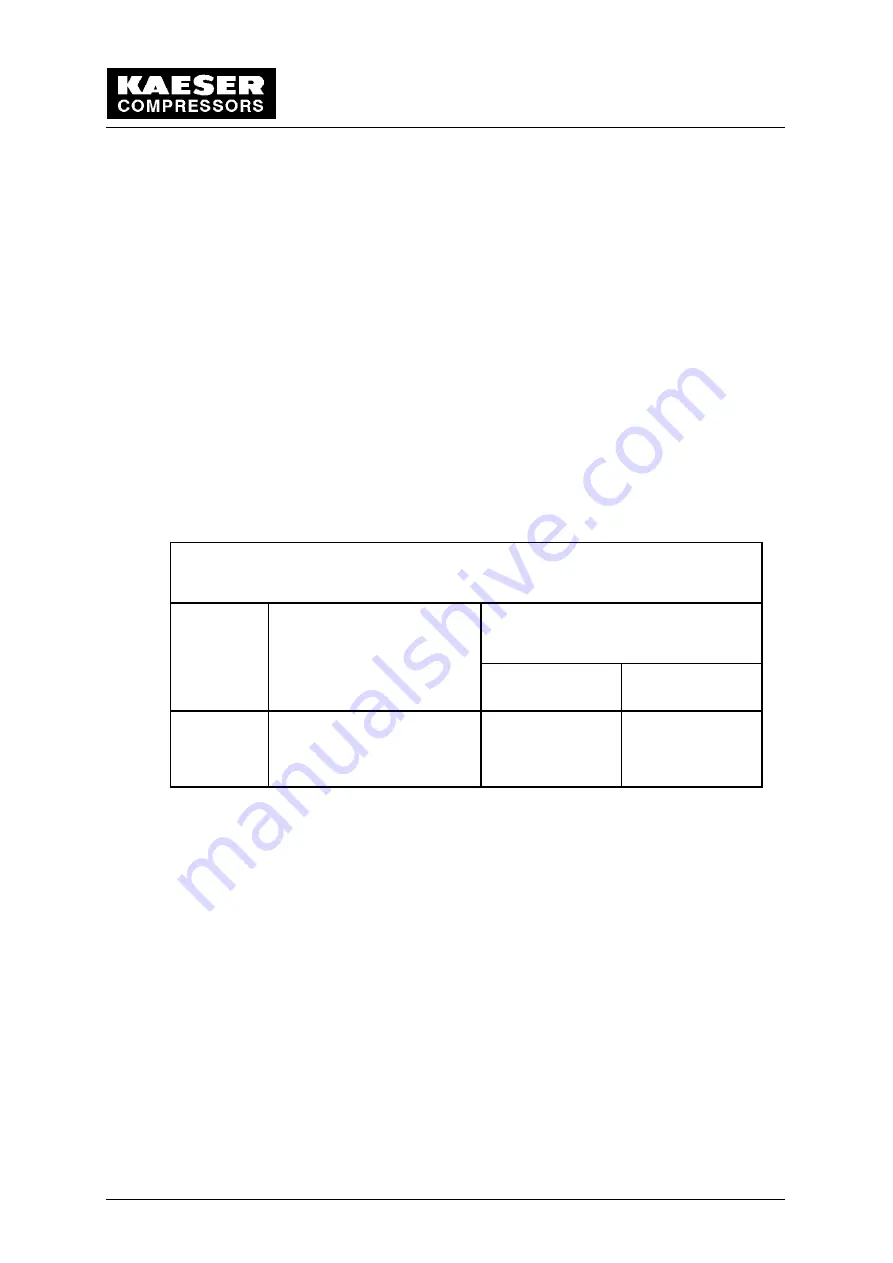

SPECIALTY KAESER LUBRICANTS

(Refer to product information to determine suitability.)

SIGMA

LUBRICANT

DESCRIPTION

MAXIMUM RECOMMENDED

CHANGE INTERVAL*

First Oil Change

Subsequent Oil

Change

S---680

FG---460

ISO 68 Synthetic Lubricant

ISO 46 Food Grade Synthetic

Fluid

6,000 Hours

2,000 Hours

8,000 Hours

3,000 Hours

*

Oil changes may need to be more frequent depending on ambient conditions.

When high ambient temperatures or dirty conditions are present, oil changes may be

necessary every 1,000 hours (4,000 hours for synthetic) or even shorter intervals. Oil

change intervals required should be determined through periodic oil analysis.

1.8.3

Compatibility of KAESER Sigma Lubricants

All the above listed KAESER Sigma lubricants are similar to mineral oil in their compatibility

with paints, seals, gaskets and hoses. The typical precautions are required when changing

over from mineral oil to KAESER synthetic hydrocarbon based lubricant.

Never mix lubricants of different types or brands.

When switching from mineral oil to a synthetic oil, the plant’s system materials must be

re---evaluated. Certain plastics are not compatible with synthetic oils. The following is a par-

tial list of acceptable and not recommended materials:

Summary of Contents for SK 19

Page 10: ...Technical Specification 1 6 ...

Page 19: ...Construction and Operation 5 15 ...

Page 20: ...Construction and Operation 5 16 ...

Page 64: ...Appendix 11 60 11 Appendix 11 1 Wiring Diagram ...

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ...Appendix 11 77 11 2 Spare Parts List ...

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......