De-commissioning, storage and disposal

Improper handling of old operating fluids and components represent a danger for the environment.

➤ Drain off fluids and dispose of them according to environmental regulations.

These include, for example, compressor oil and cooling water.

➤ Have refrigerant disposed of by authorized bodies only.

➤ Dispose of the machine in accordance with local environmental regulations.

3.5.3 Organizational Measures

➤ Designate personnel and their responsibilities.

➤ Give clear instructions on reporting faults and damage to the machine.

➤ Give instructions on fire reporting and fire-fighting measures.

3.5.4 Danger Areas

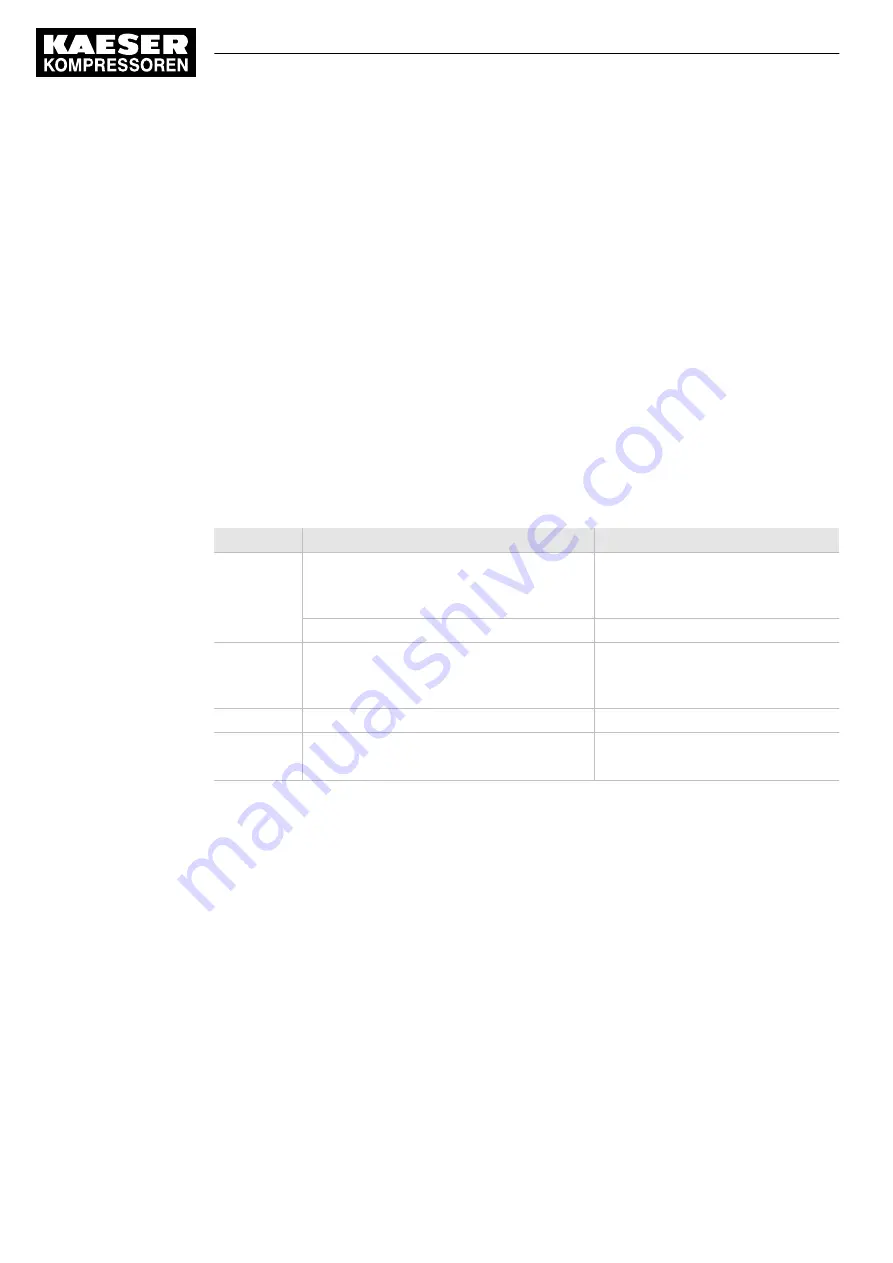

The table gives information on the areas dangerous to personnel.

Only authorized personnel may enter these areas.

Activity

Danger area

Authorized personnel

Transport

Within a 10 ft radius of the machine.

Installation personnel for transport

preparation.

No personnel during transport.

Beneath the lifted machine.

No personnel!

Installation

Within the machine.

Within 3 ft radius of the machine and its sup‐

ply cables.

Installation personnel

Operation

Within a 3 ft radius of the machine.

Operating personnel

Maintenance Within the machine.

Within a 3 ft radius of the machine.

Maintenance personnel

Tab. 20 Danger Areas

3.6 Safety devices

Various safety devices ensure safe working with the machine.

➤ Do not change, bypass or disable safety devices.

➤ Regularly check safety devices for their correct function.

➤ Do not remove or obliterate labels and notices.

➤ Ensure that labels and notices are clearly legible.

Further information More information on safety devices is contained in chapter 4, section 4.3.

3

Safety and Responsibility

3.6

Safety devices

18

Operator Manual Screw Compressor

SM Tri-Voltage, SIGMA CONTROL 2

9_5875 33 USE